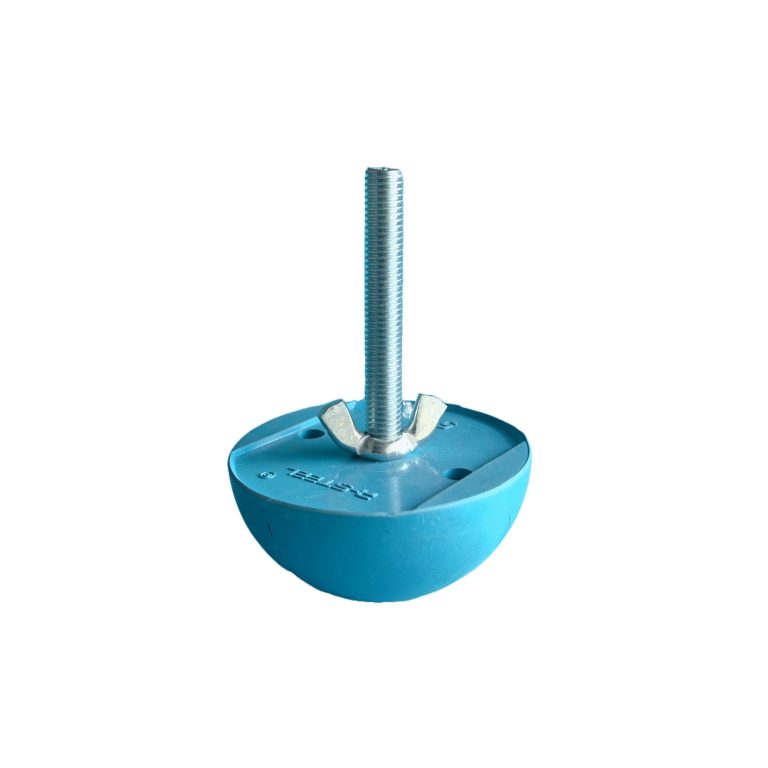

Rubber recess former are specialized tools designed for the efficient production of T-shaped components used in various applications, particularly in construction and manufacturing. These molds are made from high-quality, flexible rubber, allowing for precise shaping and consistent quality in the final products.

Product Details

T-shaped rubber molds are specialized tools designed for the efficient production of T-shaped components used in various applications, particularly in construction and manufacturing. These molds are typically made from high-quality, flexible rubber that offers durability and resistance to wear, ensuring they can withstand repeated use without significant degradation. The molds feature a precise T-shaped profile, allowing for the accurate production of components with specific dimensions and angles, which is crucial for applications requiring exact fit and alignment.

Description and Components:

Description:

T-shaped rubber molds are specialized tools designed for the production of T-shaped components used in various applications, particularly in construction and manufacturing. These molds are made from high-quality, flexible rubber, allowing for precise shaping and consistent quality in the final products.

Material:

The molds are typically constructed from durable rubber that provides flexibility and resistance to wear, ensuring longevity and repeated use without significant degradation.

Design:

The T-shaped profile is engineered to create components with specific dimensions and angles, making them suitable for various structural applications, such as brackets, connectors, and supports.

Functionality:

Applications:

Advantages:

| ITEM NO. | Size |

| JRRF013 | 1.3T |

| JRRF025 | 2.5T |

| JRRF050 | 5T |

| JRRF100 | 10T |

| JRRF200 | 20T |

| JRRF320 | 32T |