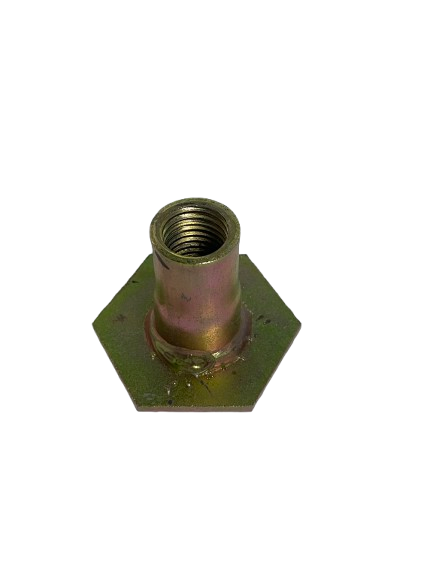

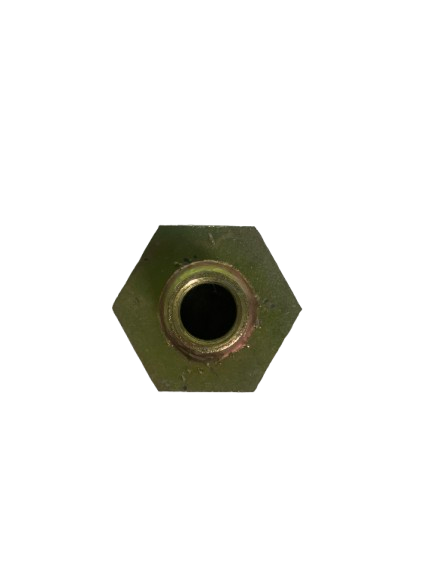

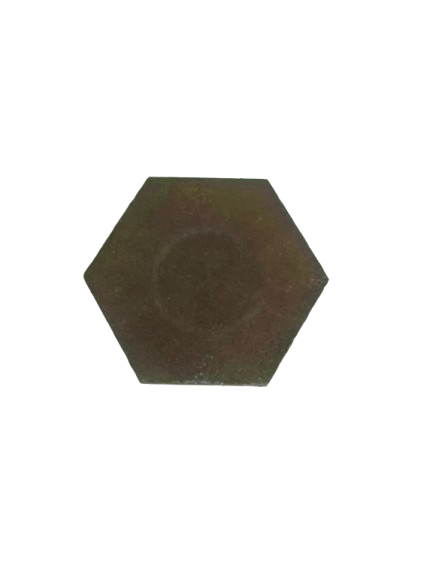

Hexagonal Base Fixing Sleeve : In the construction field, the hexagonal base fixing sleeve is primarily used to secure and connect structural components, such as steel frames, scaffolding, and prefabricated parts. Its hexagonal design allows for quick installation and removal using tools, while providing high stability and anti-torsion performance, ensuring the strength and safety of building structures. It is ideal for applications requiring high strength and reliable connections.

Functionality:

Fixing and Support: Used to securely fasten bolts or anchor rods in building structures, ensuring stability.

Load Distribution: The hexagonal design evenly distributes loads to the base material, reducing localized stress concentration.

Anti-Loosening: Prevents bolts or anchor rods from loosening due to vibration or external forces, enhancing safety.

Easy Installation: The hexagonal design allows for easy installation and removal using standard tools, improving construction efficiency.

Applications:

Steel Structure Buildings: Used for connecting steel beams, columns, and other structural components.

Concrete Structures: Used for fixing anchor rods or bolts in concrete.

Bridge Engineering: Used in bridge connections to ensure structural stability.

Mechanical Equipment Installation: Used for fixing building equipment or machinery bases.

Curtain Wall Installation: Used for fixing the support structures of building curtain walls.

Advantages:

High Stability: The hexagonal design provides better torsional and tensile strength.

Even Load Distribution: Effectively distributes loads, reducing the risk of base material damage.

Durability: Made of high-strength materials, suitable for long-term use.

Easy Installation: The hexagonal design allows for quick and easy operation with standard tools, saving time and labor.

Strong Adaptability: Suitable for various building materials and working conditions.