Roofing Nails

Importance in Construction

In the world of construction, the significance of using the right nail for the job cannot be overstated. Roofing nails are specifically designed to cope with the unique demands that roofing tasks entail. These nails play a crucial role in securing shingles and other roofing materials, ensuring durability and long-lasting performance. Using improper nails, such as common nails, could lead to roofing failures, potentially causing costly water damage and structural issues. Therefore, understanding the distinctions between roofing nails and common nails is essential for any construction or renovation project involving roofs.

Unique Features

Roofing nails are engineered with distinctive features that differentiate them from common nails. These unique characteristics are purposefully designed to address the specific challenges posed by roofing applications.

Material Composition

The material composition of roofing nails generally includes stainless steel, galvanized steel, or aluminum. These materials are chosen for their robustness and ability to withstand harsh environmental conditions. Stainless steel and galvanized steel, for instance, exhibit high resistance to rust and corrosion, factors that are critical for the longevity of roofing structures. Aluminum, although lighter, provides adequate durability and is often used in specific roofing scenarios where weight might be a concern.

Corrosion Resistance

One of the hallmark features of roofing nails is their enhanced corrosion resistance. Given that roofing materials are continuously exposed to the elements, the nails holding them must be able to resist moisture and other corrosive agents. Galvanized roofing nails, which are coated with a layer of zinc, offer superior protection against rust, thereby extending the life of the roofing assembly. This resistance to corrosion ensures that the integrity of the roofing structure is maintained over time, even under extreme weather conditions.

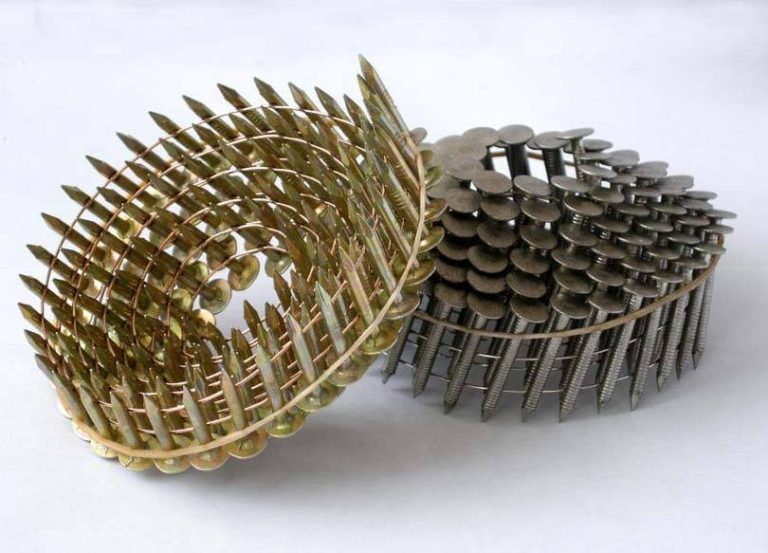

Head Design

The head design of roofing nails is another critical aspect that sets them apart from common nails. Roofing nails typically have a larger, more substantial head, which provides a larger surface area for securing shingles and other roofing materials. This design reduces the risk of the nails pulling through the materials, ensuring a firmer hold. The broader head also helps to distribute the load more evenly, which is vital in maintaining the structural integrity of the roof.

Overall, the unique features of roofing nails—such as their material composition, corrosion resistance, and head design—are tailored to meet the specific needs of roofing applications. Understanding these features enables construction professionals and DIY enthusiasts to select the right type of nail, ultimately contributing to the safety, durability, and longevity of roofing projects.

Common Nails

General Usage in Carpentry

Common nails are a staple in various carpentry and general construction projects. Unlike roofing nails, these nails are versatile and used in a wide array of applications, from framing and decking to finishing and trim work. They are typically employed where a robust and reliable fastener is required, but the nails themselves will not be subjected to the same rigorous environmental conditions as roofing nails. Despite their name, common nails are far from ordinary and are fundamental in ensuring the structural integrity of numerous building projects.

Typical Characteristics

Length and Gauge Variability

One of the primary characteristics of common nails is their variability in length and gauge. These nails come in a range of sizes to accommodate different construction needs. For instance, shorter common nails might be used in delicate trim work, while longer, thicker nails are better suited for heavy-duty framing tasks. The gauge, or thickness, of the nail affects its strength and holding power. This variability allows builders and carpenters to select the most appropriate nail for each specific task, ensuring optimal results and structural soundness.

Different Types of Heads

Common nails also feature diverse head designs tailored to specific use cases. The most prevalent type is the flat head, which provides a solid driving surface and ensures a flush finish. However, other head designs such as brad and finish heads are used in more delicate applications where a more subtle appearance is desired. These head types are typically smaller and can be countersunk or filled to achieve a seamless look. The variety in head design among common nails highlights their adaptability and the necessity of choosing the right type for each particular job.

Key Differences Between Roofing Nails and Common Nails

Primary Applications

The primary difference between roofing nails and common nails lies in their applications. Roofing nails are specifically designed for securing roofing materials such as shingles and felt, whereas common nails are used for general carpentry and construction tasks. The unique requirements of each application dictate the design and material of the nails. Roofing nails, for example, need to withstand outdoor conditions and hold materials that are exposed to wind, rain, and temperature fluctuations. Common nails, on the other hand, are more versatile but generally operate in less extreme environments.

Structural Design Differences

Structurally, roofing nails and common nails differ in significant ways. Roofing nails usually have a shorter shank and a larger head compared to common nails. This design is intended to provide greater holding power for roofing materials and minimize the risk of nails being pulled out by external forces. The shank of a roofing nail might also be barbed or twisted to enhance its grip. Common nails, however, tend to have a simpler design with a longer shank, which makes them suitable for penetrating deeper into wood and providing robust support for various construction applications.

Performance Under Various Weather Conditions

Performance under adverse weather conditions is another key aspect where roofing nails outshine common nails. Roofing nails are designed to resist the corrosive effects of moisture, extreme temperatures, and UV radiation. Their corrosion-resistant coatings, such as galvanization, provide an added layer of protection that prolongs the lifespan of the nail and the roofing structure. Common nails, while durable, are not typically engineered with the same level of weather resistance. As such, using common nails for roofing tasks could lead to premature rusting and failure, compromising the integrity of the roof.

Selecting the Right Nail for Your Project

Determining Project Requirements

Selecting the right nail for your project is a critical step that involves understanding the specific requirements of your task. For roofing projects, it is essential to use roofing nails that can withstand environmental stresses and provide adequate holding power for shingles and other materials. For general carpentry or interior work, common nails may be more suitable due to their versatility and availability in various sizes and types. Assessing the needs of your project will guide you in making an informed decision.

Evaluating Environmental Factors

Environmental factors play a significant role in nail selection. For projects exposed to harsh weather conditions, like roofing, it is imperative to choose nails with high corrosion resistance. Roofing nails, particularly those made of galvanized steel or stainless steel, are ideal for such environments. In contrast, for indoor projects or environments with controlled conditions, common nails will typically suffice. Evaluating these factors ensures that the nails you choose will perform effectively and offer lasting durability.

Cost and Availability Considerations

Lastly, cost and availability are practical considerations when selecting nails for your project. Roofing nails, given their specialized nature and enhanced features, can be more expensive than common nails. However, the investment is justified by their critical role in ensuring the longevity and functionality of a roof. Common nails are more readily available and usually less expensive due to their broad usage. Balancing cost with the specific needs of your project is essential in making the best choice.

By understanding the distinct attributes and applications of roofing nails and common nails, you can make informed decisions that will contribute to the success and durability of your construction projects.

BAOQI, established in 2010, is a company based in Qingdao, China, specializing in the production and export of various products.Our main product range includes precast systems, scaffolding systems, formworks, coil roofing nails, farm machinery parts, steel frame construction structures, and more. We also offer a wide range of precast and mold accessories such as lifting anchor systems, rapid lifting systems, threaded socket systems, cast-in loops and connection boxes, cast-in anchor channels, coil inserts, and tying solutions. BAOQI‘s products are carefully tested to meet strict quality requirements and industry standards before shipment. With over 10 years of development, our products have gained popularity in countries like Australia, Denmark, Finland, France, UK, Germany, Canada, USA, and Middle East countries. BAOQI is committed to providing customers with the best quality products, competitive prices, and timely delivery. For more information about our products, you can visit their homepage.