What Are Eye Bolts and Their Uses?

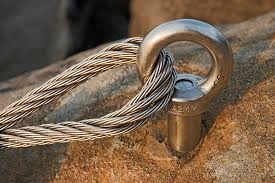

Eye bolts are essential fasteners and hardware components, designed with a loop shaped like an eye at one end. They play a crucial role in various applications, including lifting, rigging, and securing loads. Utilized in construction, marine, and industrial projects, eye bolts are favored for their versatility and reliability. Due to their strength and ease of use, they are integral in ensuring safety and stability in different settings.

Various Types of Eye Bolts

Standard Eye Bolts

Standard eye bolts are among the most commonly used types in various applications. These eye bolts typically feature a threaded shank and a looped end. They are widely utilized in construction, shipping, and maintenance activities where securing ropes or cables is necessary. Standard eye bolts are appreciated for their ease of installation and dependable performance in everyday tasks.

Shoulder Eye Bolts

Shoulder eye bolts feature a shoulder between the shank and the loop, providing additional strength and stability. This design modification enables them to manage angular loads more effectively, minimizing the risk of bending or deformation. Thanks to their increased durability, shoulder eye bolts are commonly employed in lifting and rigging tasks where load alignment is essential. They are particularly suitable for heavy-duty lifting and intricate rigging systems.

Lag Eye Bolts

Lag eye bolts, also known as lag screws, feature a pointed, threaded shank designed to be driven into wood or other soft materials. These eye bolts are commonly used in structural applications, such as securing wooden beams or attaching hardware to wooden surfaces. The main advantage of lag eye bolts is their capacity to create a strong holding force within the material, making them suitable for projects that require robust and reliable fastening.

Screw Eye Bolts

Screw eye bolts, resembling lag eye bolts but generally smaller, are designed for lighter loads. With a screw-threaded shank, these bolts are commonly used in non-industrial settings. They are ideal for hanging picture frames, securing wires, or fulfilling various gardening requirements. Screw eye bolts offer a practical and effective solution for household tasks where moderate holding strength and simple installation are needed.

Machinery Eyebolts (Heavy-Duty)

Machinery eyebolts are crafted to withstand significant loads and stress, making them indispensable in heavy-duty industrial applications. These eye bolts are generally used in machinery lifting, construction equipment handling, and other scenarios requiring substantial load-bearing capacity. Constructed from high-strength materials, machinery eye bolts are designed to meet strict safety standards, ensuring reliability and performance under demanding conditions.

Materials Used in Manufacturing Eye Bolts

Stainless Steel Eye Bolts

Stainless steel eye bolts provide numerous benefits, notably their excellent resistance to rust and corrosion. This characteristic makes them perfect for marine environments, chemical processing plants, and outdoor settings where frequent exposure to moisture or harsh chemicals occurs. Moreover, stainless steel eye bolts retain their structural integrity and appearance over time, offering enduring durability and performance across various conditions.

Galvanized Steel Eye Bolts

Galvanized steel eye bolts are coated with a layer of zinc, imparting them with enhanced resistance to corrosion and wear. This makes them suitable for applications where the fasteners are exposed to the elements, such as in construction, agricultural machinery, and outdoor structural projects. The galvanization process extends the lifespan of the eye bolts, ensuring they remain functional and reliable over extended periods.

Load Limits and Safety Considerations

Understanding Load Ratings for Different Types of Eye Bolts

Understanding the load ratings for different types of eye bolts is crucial to ensuring their safe and effective use. Each type of eye bolt comes with its specific load rating, which indicates the maximum weight it can safely handle. For example, standard eye bolts are typically rated for moderate loads, while machinery eye bolts are designed for heavy-duty applications. The load rating also depends on the material used in the manufacturing of the eye bolt. Stainless steel and galvanized steel varieties tend to offer higher load capacities due to their enhanced strength and durability. It is essential to refer to the manufacturer’s specifications and guidelines to determine the appropriate load rating for your specific needs.

Safety Tips When Using Eye Bolts

Ensuring safety is crucial when utilizing eye bolts in any situation. Remember these vital safety guidelines:.

- Proper Installation:Always ensure that the eye bolt is installed correctly, following the manufacturer’s instructions. Incorrect installation can lead to failure under load.

- Load Alignment:Make sure the load is aligned correctly with the eye bolt. Improperly aligned loads can exert additional stress on the eye bolt, increasing the risk of bending or breakage.

- Regular Inspections:Regularly inspect the eye bolts for signs of wear, corrosion, or damage. Replace any eye bolts that show signs of deterioration to maintain safety.

- Use Appropriate Lubricants:In environments where eye bolts are exposed to corrosive elements, applying appropriate lubricants can help protect the threads and prolong the life of the eye bolt.

How to Choose the Right Type of Eye Bolt for Your Needs

Choosing the right type of eye bolt for your needs involves considering several key factors to ensure safety, efficiency, and longevity.

Factors to Consider

Application Requirements

Different applications require different types of eye bolts. Standard eye bolts may be sufficient for basic tasks, but more demanding applications, such as machinery lifting, might necessitate the use of shoulder eye bolts or machinery eyebolts. Consider the specific requirements of your project to determine which type of eye bolt is most suitable.

Material Compatibility

The material of the eye bolt is another critical factor to consider. Stainless steel eye bolts offer excellent resistance to corrosion, making them ideal for marine and outdoor applications. On the other hand, galvanized steel eye bolts provide robust protection against rust and wear in more general environments. Choosing the right material ensures the eye bolt performs well under the conditions it will be exposed to.

Load Capacity

Always check the load capacity of the eye bolts you plan to use. Overloading an eye bolt can result in catastrophic failure, leading to serious safety hazards. Evaluate the weight and nature of the load, and select an eye bolt with a suitable load rating. For heavy-duty lifting, machinery eyebolts or shoulder eye bolts with high load capacities are advised.

Introduction to BAOQI: A Leading Provider of Quality Eye Bolts

BAOQI stands out as a reliable manufacturer and supplier of top-notch eye bolts. Renowned for their dedication to quality and innovation, BAOQI provides an extensive array of eye bolts designed to meet a wide range of industrial requirements. By implementing rigorous quality control procedures, BAOQI guarantees that each product meets the highest industry standards. Their broad catalog includes various types of eye bolts suitable for both general and specialized uses.

Conclusion: Summarizing the Different Types of Eye Bolts and Their Applications

In summary, eye bolts are versatile and essential components in various industrial, construction, and marine applications. Understanding the different types of eye bolts—such as standard eye bolts, shoulder eye bolts, lag eye bolts, screw eye bolts, and machinery eyebolts—helps in selecting the right one for specific needs. BAOQI, a reputable manufacturer, offers a diverse range of high-quality eye bolts that cater to these varied applications.

Considering factors like application requirements, material compatibility, and load capacity ensures that the chosen eye bolt provides the necessary safety and performance. By adhering to load limits and safety guidelines, users can maximize the reliability and longevity of the eye bolts, ensuring the success and safety of their projects.