Understanding Connector Couplers

Connector couplers are essential components that facilitate the connection between various systems and devices, enabling them to work harmoniously. These devices are critical in various sectors, including telecommunications, construction, and manufacturing, as they ensure efficient communication and functionality between connected elements. The significance of connector couplers lies not just in their ability to join parts but also in their role in maintaining system integrity and performance under different operational conditions. The careful selection and use of high-quality connector couplers can lead to enhanced reliability, reduced downtime, and overall cost-effectiveness in system management.

Common Uses in Various Industries

In the telecommunications industry, connector couplers are pivotal for establishing connections between antennas, transmission lines, and devices, ensuring high-quality signal transmission. The construction sector often employs connector couplers for joining pipes, beams, and other structural components, allowing for versatile designs and ease of assembly. Additionally, in manufacturing, connector couplers are utilized in assembly lines to facilitate smooth operations and quick disassembly when maintenance is required. Their widespread applicability highlights their importance across multiple industries.

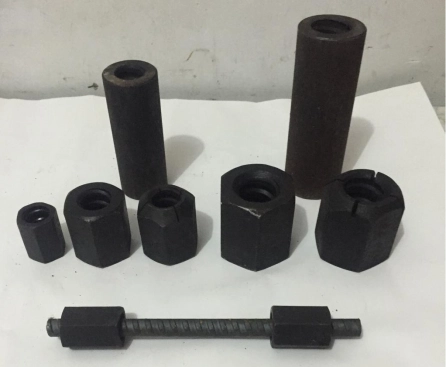

Types of Mechanical Connector Couplers

Mechanical connector couplers are primarily used in construction and manufacturing environments where strong physical connections are required. Various types of mechanical couplers serve specific needs based on their design, installation requirements, and application scenarios.

Threaded Couplers

Threaded couplers feature external and internal threads that allow them to be securely fastened to corresponding threaded components. This design characteristic provides a robust connection that can withstand significant stress, making them ideal for applications that demand high strength. Common use cases for threaded couplers include plumbing, where they join pipes, and in structural applications where beams and columns are connected. Their reliability in heavy-duty scenarios contributes to their popularity in the industry.

Compression Couplers

Compression couplers operate by forcing two components together through a tightening mechanism. This working mechanism ensures a tight seal which is crucial for preventing leaks in fluid systems. Typically employed in plumbing and hydraulic applications, compression couplers are favored in industries requiring secure connections under pressure. The ability to create a lasting and leak-proof connection makes compression couplers essential in environments dealing with high fluid flow.

Push-Fit Couplers

Push-fit couplers simplify the installation process by allowing components to be connected with a simple push, eliminating the need for tools or complex assembly procedures. These couplers are particularly advantageous in situations where quick connections are needed, such as in temporary installations or frequent disassemblies. While they offer significant ease of use, push-fit couplers can be less robust in high-demand environments, which might limit their applications in some industries.

Electrical Connector Couplers: An In-depth Look

Electrical connector couplers play a crucial role in enabling the transfer of electrical signals between various devices and systems. These couplers come in different designs, each suited for specific applications to ensure optimal performance.

Coaxial Couplers

Coaxial couplers consist of an inner conductor surrounded by an insulating layer and an outer conductor, which together facilitate the transmission of radio frequency signals. This structure allows for minimal signal loss and forms a crucial part of communication systems. Coaxial couplers are commonly used in television and internet connections, where maintaining signal integrity is vital. Their application spectrum extends to various telecommunications infrastructure, underscoring their importance in modern communication networks.

Fiber Optic Couplers

Fiber optic couplers are specialized devices that allow for the mating of optical fibers, enabling the transfer of light signals. There are several types of fiber optic couplers, including Fused Biconical Taper (FBT) and Planar Lightwave Circuit (PLC) couplers.

Different Types

FBT couplers are recognized for their ability to combine or split light signals with minimal loss, making them suitable for a wide range of applications in telecommunications. PLC couplers, on the other hand, utilize a planar lightwave circuit technology that allows for more complex configurations and superior performance in multi-channel systems.

Benefits in Telecommunication Networks

The integration of fiber optic couplers into telecommunication networks enhances signal quality and bandwidth, facilitating modern communication demands. Their ability to support high-speed data transmission is vital for both current and future networking technologies.

Criteria for Selecting the Right Connector Coupler

Material Considerations: Metal vs. Plastic vs. Hybrid

When selecting connector couplers, the choice of material plays a pivotal role in their overall performance, durability, and cost-effectiveness. Metal connector couplers are often favored for their superior strength and resistance to high stresses, making them ideal for heavy-duty applications. They are less susceptible to temperature fluctuations and exhibit better resistance to environmental degradation compared to their plastic counterparts. Conversely, plastic connector couplers are usually lighter and more cost-effective, suitable for applications where weight savings are critical, and the operational environment is less demanding. Hybrid models that incorporate both metal and plastic elements provide a balance between durability and flexibility, catering to a wide range of application scenarios.

Compatibility with Existing Systems and Standards

Ensuring compatibility with existing systems and industry standards is crucial when selecting connector couplers. High compatibility helps to avoid issues related to misalignment, performance inefficiencies, and eventual system failures that could arise from incompatible couplers. It is essential to consider the physical dimensions, coupling mechanisms, and operational characteristics of the couplers to ensure they fit seamlessly with the systems they’re meant to connect. Adherence to established standards, such as IEC, ISO, or specific industry standards, enhances interoperability and reliability across different components, making integration easier and more effective.

Environmental Factors: Temperature, Corrosion Resistance, etc.

Environmental conditions significantly influence the selection of appropriate connector couplers. Factors such as temperature extremes, humidity, and exposure to corrosive substances need to be evaluated thoroughly. Connector couplers used in outdoor applications or harsh industrial settings should possess corrosion resistance to extend their lifespan and reduce maintenance costs. Additionally, temperature ranges are important to consider; couplers must be durable enough to withstand extreme heat or cold without losing their mechanical properties or operability. Choosing couplers designed to handle specific environmental challenges ensures reliable long-term performance and minimizes operational disruptions.

Performance Metrics: Durability, Load Bearing Capacity, etc.

Assessing the performance metrics of connector couplers is vital for ensuring they meet the operational demands of their intended application. Durability is a key attribute, reflecting a coupler’s ability to resist wear and tear from frequent use and environmental exposure. Load bearing capacity indicates how much force or weight a coupler can handle, which is particularly critical in construction and manufacturing applications where structural integrity is paramount. Other performance indicators may include ease of installation, maintenance requirements, and how well the couplers can sustain mechanical connections through vibrations or shock loadings. High-performance couplers contribute to system reliability and efficiency.

Introduction to BAOQI’s Range of Connector Couplers

Overview of BAOQI as a Leading Brand in Connector Technology

BAOQI has established itself as a reputable brand within the connector coupler market, known for its innovative and high-quality products. With a comprehensive product portfolio that meets diverse application requirements, BAOQI has built a solid reputation for excellence and reliability in connector technology. The company employs advanced manufacturing processes and stringent quality control measures to ensure that each product meets or exceeds industry standards. BAOQI’s commitment to continuous research and development allows it to remain competitive and responsive to changing market needs.

Unique Selling Points of BAOQI’s Products

BAOQI’s products stand out in the marketplace due to several unique selling points, including a focus on customization, robust performance, and exceptional customer service. The ability to tailor connector couplers to fit specific applications ensures that customers receive the optimal solution for their unique challenges. BAOQI prides itself on leveraging cutting-edge materials and innovative designs to enhance durability and performance across diverse settings. Furthermore, an emphasis on customer satisfaction through comprehensive support and after-sales service sets BAOQI apart as a preferred partner in connector technology.

Popular Models and Their Applications

Within BAOQI’s extensive lineup of connector couplers, several models have gained popularity across various industries due to their reliability and functionality. For example, the BAOQI Series 3000 connector is widely recognized in the telecommunications sector for its high-speed data transmission capabilities. In contrast, the BAOQI Heavy-Duty Coupler is often deployed in construction sites where heavy loads demand robust connectors. Other models cater to specialized applications, such as water management systems or medical devices, demonstrating BAOQI’s versatility in addressing the specific needs of different markets.

Future Trends in Connector Coupler Technologies

Advances in Material Science

The connector coupler industry is poised for exciting advancements, particularly in material science. Emerging materials designed to enhance conductivity, resistance to environmental factors, and overall performance will reshape existing product offerings. For example, the development of nano-composite materials could lead to lighter, stronger couplers that maintain mechanical integrity under demanding conditions. Furthermore, the rise of biodegradable plastics in certain applications can offer environmentally friendly alternatives for connector couplers, appealing to industries focusing on sustainability and eco-consciousness in their operations.

Innovations in Design for Enhanced Durability

Continuous innovations in design are also critical to elevating the performance and lifespan of connector couplers. Recent trends have seen the incorporation of modular designs that allow for easier replacement of components without having to discard the entire unit, thus promoting sustainability. Improved sealing technologies to protect against moisture and dust will significantly enhance the durability of couplers in harsh environments. Moreover, approaches such as 3D printing enable customized production of couplers tailored to specific application needs, facilitating rapid prototype development and reducing time-to-market for new designs.

Integration with IoT and Smart Manufacturing Systems

The integration of the Internet of Things (IoT) into connector coupler technologies is an emerging trend that offers enormous potential for the future. Smart connector couplers equipped with sensors can monitor their performance in real-time, providing valuable data for predictive maintenance and enhancing operational efficiency. These couplers can communicate with smart manufacturing systems, enabling factory automation by providing health status updates and triggering corrective actions when necessary. By leveraging data analytics, industries can optimize their connector usage and improve system performance while minimizing downtime and maintenance costs.