Basics of a Lifting Anchor System

Definition and Purpose

A lifting anchor system is a critical component used in construction and engineering to facilitate the lifting and transportation of heavy concrete elements safely and efficiently. These systems are essential for ensuring structural integrity during the movement of precast structures, allowing for precise and controlled lifting operations. The primary purpose of a lifting anchor system is to provide a secure attachment point in concrete elements, enabling cranes and other lifting devices to hoist and transport them without causing damage.

Key Components

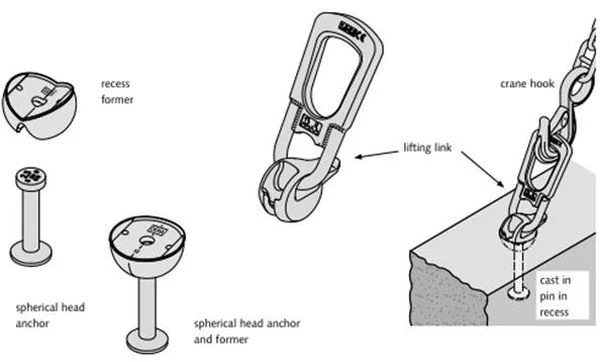

A lifting anchor system typically comprises several key components that work in unison to ensure safe lifting operations:

- Anchors:These are embedded into the concrete and serve as the primary attachment points for lifting. They are made from high-strength materials to withstand significant loads.

- Lifting Clutches:These devices attach to the anchors and connect to the lifting apparatus. They ensure a firm grip on the anchors and facilitate the transfer of loads.

- Reinforcement Elements:Reinforcing bars or mesh are often used around the anchors to distribute the loads and prevent concrete failure.

- Protection Caps:These are used to protect the anchors from damage or contamination during the casting and curing phases.

Types of Lifting Anchor Systems

Cast-in-place Systems

Features and Applications

Cast-in-place lifting anchor systems are embedded into the concrete during the pouring process. They are designed to become an integral part of the concrete element, providing a permanent and robust lifting solution. Key features include:

- Custom Fit:These anchors can be customized to fit specific project requirements, ensuring optimal strength and performance.

- High Load Capacity:Due to their integration with the concrete, cast-in-place systems can handle significant loads, making them ideal for large and heavy elements.

- Durability:These systems are made from durable materials like steel, ensuring longevity and reliability.

Cast-in-place systems are commonly used in projects where heavy prefabricated concrete elements need to be lifted, such as bridges, large building components, and industrial structures.

Post-installed Systems

Features and Applications

Post-installed lifting anchor systems are attached to the concrete element after it has been cast and cured. These systems offer flexibility and can be installed without altering the existing structure. Key features include:

- Versatility:Post-installed systems can be used in various situations, including retrofitting applications or where cast-in-place anchors were not feasible.

- Ease of Installation:These systems can be quickly and easily installed, saving time and reducing labor costs.

- Adjustability:They can be adjusted or removed as needed, making them adaptable to changing construction needs.

Post-installed systems are particularly useful in renovation projects, where existing structures need to be lifted or moved, such as in structural repairs or modifications.

How Lifting Anchor Systems Work

Load Distribution Mechanisms

The effectiveness of a lifting anchor system depends on its ability to distribute the load evenly across the concrete element. The anchors are strategically positioned to ensure balanced lifting, minimizing the risk of structural damage or failure. Reinforcement elements, such as rebar, are used around the anchors to help distribute the loads and prevent concrete cracking. This distribution mechanism ensures the safety and stability of the lift, protecting both the concrete element and the workers involved in the operation.

Installation Process

Installing a lifting anchor system involves several steps, beginning with the design phase, where engineers determine the appropriate type and configuration of anchors needed based on the load requirements and concrete specifications. For cast-in-place systems, the anchors are positioned in the formwork before the concrete is poured. Proper positioning and alignment are crucial for ensuring the anchors can handle the required loads.

For post-installed systems, anchor holes are drilled into the cured concrete at designated points. The anchors are then inserted and secured using specialized adhesives or mechanical means. The lifting clutches are attached to the anchors, and load tests are conducted to verify the stability and strength of the system. This meticulous process ensures that the lifting anchor system performs reliably under the specified conditions.

Advantages of Using Lifting Anchor Systems

Safety Benefits

The use of lifting anchor systems significantly enhances safety on construction sites. By providing secure and reliable attachment points, these systems minimize the risk of accidents and injuries associated with lifting and moving heavy concrete elements. Lifting anchors ensure that the loads are evenly distributed, reducing the chances of structural failure and protecting workers from potential hazards. Additionally, lifting anchor systems often come with safety features such as load indicators and fail-safe mechanisms, further contributing to a safer work environment.

Efficiency in Construction Projects

Lifting anchor systems greatly improve efficiency in construction projects. By enabling precise and controlled lifting operations, these systems reduce the time and labor required for handling heavy concrete elements. This efficiency translates into faster project completion times and lower overall costs. The ability to lift and position elements accurately also improves the quality of construction work, as components can be installed with greater precision. As a result, projects benefit from both time savings and enhanced construction quality.

Common Applications

Building Construction

Lifting anchor systems are widely used in building construction to handle large and heavy concrete components such as slabs, beams, columns, and panels. These systems facilitate the efficient assembly of prefabricated elements, allowing for the rapid erection of structures. The secure attachment points provided by lifting anchors ensure that building components are lifted and positioned accurately, contributing to the structural integrity of the finished construction. This application is particularly common in high-rise buildings, where precise lifting is critical for safety and project success.

Prefabricated Concrete Elements

In the realm of prefabricated concrete elements, lifting anchor systems play a crucial role in the transportation and installation of components manufactured off-site. These elements include precast walls, modular units, and bridge sections, among others. Lifting anchors provide secure attachment points for hoisting and moving these heavy items from the manufacturing facility to the construction site. The ability to handle large prefabricated elements with ease enhances the efficiency of modular construction methods, reducing lead times and optimizing resource utilization.

Selecting the Right Lifting Anchor System

Factors to Consider

Load Capacity Needs

When selecting a lifting anchor system, it is essential to consider the load capacity requirements of the concrete elements being handled. The chosen anchors must be capable of withstanding the maximum loads expected during lifting operations. Engineers should conduct a thorough analysis of the weight, dimensions, and center of gravity of the elements to determine the appropriate load capacity for the anchors. This ensures that the lifting system can safely support the loads without risking structural failure.

Material Compatibility

Material compatibility is another critical factor in selecting a lifting anchor system. The anchors and lifting clutches must be compatible with the concrete and any reinforcement materials used in the structure. Engineers should take into account the composition and properties of the concrete to ensure that the anchors can achieve a secure bond and maintain their integrity over time. Additionally, the materials used in the lifting system should be corrosion-resistant and capable of withstanding environmental conditions to ensure long-term durability.

Industry Standards and Regulations

Compliance Requirements

Lifting anchor systems must adhere to industry standards and regulations to ensure safety and reliability. Compliance with these requirements involves following guidelines set forth by organizations such as ASTM International, the American Concrete Institute (ACI), and the European Committee for Standardization (CEN). These standards outline the design, testing, and performance criteria for lifting anchors, ensuring that they meet stringent safety and quality benchmarks. Compliance with these standards is critical for preventing accidents and ensuring the overall integrity of lifting operations.

Certification Processes

Certification processes are in place to verify that lifting anchor systems meet industry standards and regulations. Manufacturers of lifting anchors must undergo rigorous testing and evaluation to obtain certification from recognized authorities. This certification process involves extensive testing of the anchors’ load-bearing capacity, durability, and material properties. Certified lifting anchor systems provide assurance to project stakeholders that the products meet the required safety and performance standards, reducing the risk of failures and accidents during construction.

Maintenance and Inspection of Lifting Anchor Systems

Regular Maintenance Practices

Regular maintenance of lifting anchor systems is essential to ensure their continued performance and safety. Maintenance practices include inspecting the anchors and lifting clutches for signs of wear, corrosion, or damage. Any compromised components should be repaired or replaced promptly to prevent failures during lifting operations. Lubrication of moving parts and cleaning of the anchors to remove debris and contaminants are also important maintenance tasks. Implementing a routine maintenance schedule helps extend the lifespan of the lifting system and ensures its reliability.

Inspection Guidelines

Inspection of lifting anchor systems should be conducted by qualified personnel at regular intervals and before each use. Inspections involve a detailed examination of the anchors, lifting clutches, and reinforcement elements to identify any signs of wear, damage, or misalignment. Load tests may be performed to verify the strength and stability of the system under simulated lifting conditions. Documentation of inspection findings and any corrective actions taken is crucial for maintaining a comprehensive record of the system’s condition. Adhering to these inspection guidelines helps prevent accidents and ensures the safe operation of lifting anchor systems.

Innovations in Lifting Anchor Systems

Recent Technological Advancements

The field of lifting anchor systems has seen significant technological advancements in recent years. Innovations include the development of high-strength materials that provide enhanced load-bearing capacity and durability. Advanced manufacturing techniques, such as precision casting and 3D printing, have improved the accuracy and consistency of anchor production. Additionally, the integration of smart technology, such as load monitoring sensors and automated lifting systems, has enhanced the safety and efficiency of lifting operations. These technological advancements continue to drive the evolution of lifting anchor systems, providing construction professionals with more reliable and effective tools for their projects.

BAOQI Lifting Anchors are essential components used in construction projects for lifting and securing heavy loads. These anchors are designed to provide a safe and efficient lifting solution, ensuring the stability and integrity of the structure.

BAOQI Lifting Anchors are made from high-quality materials such as steel or stainless steel, ensuring their strength and durability. They are available in various sizes and capacities to accommodate different lifting requirements. These anchors are designed with a threaded or bolted connection, allowing for easy installation and removal.

The BAOQI Lifting Anchors are commonly used in applications such as lifting precast concrete elements, structural steel components, and other heavy objects. They are widely used in the construction of bridges, buildings, and infrastructure projects.

These lifting anchors are designed to distribute the load evenly, preventing any potential structural failures or damage. They are tested and certified to meet international safety standards, ensuring their reliability and performance.

BAOQI Lifting Anchors are trusted by professionals in the construction industry for their quality and efficiency. They are an essential tool for lifting and securing heavy loads, providing a safe and reliable solution for construction projects.