In construction, the need for reliable, efficient, and cost-effective solutions for lifting, securing, and positioning components is paramount. Among these solutions, hairpin anchors have emerged as a critical component in lifting systems, particularly in the precast concrete industry. This guide explores the role and significance of hairpin anchors, highlighting their benefits, applications, and why they are essential for various industries. Additionally, we will dive into how BaoQi, a leader in manufacturing high-quality forging, casting, and punching parts, provides hairpin anchors that exceed industry standards for safety, durability, and performance.

Understanding Hairpin Anchors: A Game-Changer in Construction

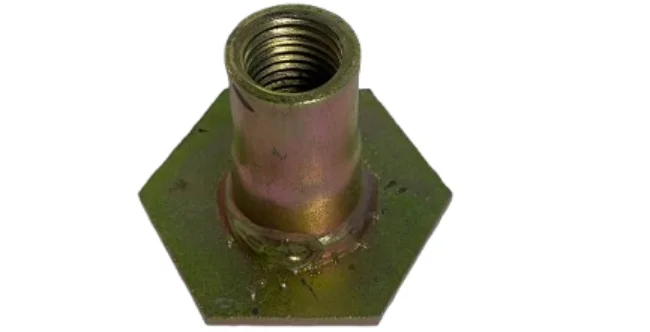

Hairpin anchors represent special lifting equipment designed to support increased loads than normal when transitional lifts from horizontal to vertical edges are made. The anchor consists of a generally bent metal rod or wire that can take many shapes, popularly the form of a hairpin, from durable materials including stainless steel, carbon steel, and galvanized steel. Typically, such kinds of anchors have been embedded inside concrete structures, which will allow creating a secured lifting point from cranes, machinery, and other equipment.

Hairpin anchors are designed to distribute the stress evenly in order to minimize damage to concrete. Castellations on the head of the anchor prevent concrete spalling due to cracking while the anchor is being subjected to the lifting forces. Robust in design, it will withstand great loads and, as such, is commonly used in projects requiring heavy-duty lifting.

Hairpin anchors are also indispensible in today’s construction on account of the versatility and strength they can offer. From building construction to civil engineering, and even to offshore operations, their application is quite wide.

Benefits that Accrue from Hairpin Anchors

1. Enhanced Lifting Capacity and Safety

Among the numerous advantages afforded by hairpin anchors, it will be found that lifting operations can also carry larger loads. Castellations around the head provide additional protection to the concrete panels from spalling caused by heavy precast elements during lifting. This further increases safety levels in terms of avoiding structural damage at construction time, minimizing repairs afterward, and improving safety records.

2. Versatility and Application Across Multiple Sectors

Hairpin anchors have a wide usage in many areas, as their application is not limited to a single area; hence, these anchors are highly versatile. The anchors are very commonly used in:

- Precast Concrete Lifting: Hairpin anchors are utilized in the precast concrete industry to lift and place panels, beams, columns, and slabs. In most instances, they ensure the process of lifting is smooth and secure, particularly in those projects that require handling of heavy precast components.

- Civil Engineering and Infrastructure Projects: Be it securing guardrails, signposts, or any other structural elements to concrete roadways, hairpin anchors do ensure robustness in installations to last long. They also apply in anchoring building elements, such as HVAC systems and structural steel to concrete foundations.These anchors are used in offshore installations and shipyards for handling heavy marine equipment and components. Galvanization gives them resistance to corrosion, thus being suitable for harsh weather conditions outdoors.

- Heavy Machinery and Equipment Lifting: Hairpin anchors are also used in factories and workshops for lifting machinery and equipment during assembly or maintenance.

The flexibility in their application makes hairpin anchors relevant in various areas where anchoring systems need to be employed in keeping structures safe and stable.

3. Corrosion Resistance for Long Life

For example, the hairpin anchors by BaoQi are hot-dipped galvanized, hence very resistant to corrosion. Corrosion resistance becomes an essential requirement in most building environments whenever the anchor is exposed to bad weather conditions, moisture, or even chemicals. That is why such materials as stainless steel or galvanized steel maintain the integrity of hairpin anchors over time and ensure durability and longevity for the anchored structures.

4. Simplified Installation Process

One of the prime advantages of hairpin anchors is that they have a very simple and effective method of installation. For the installation of these anchors, merely a drilled hole and the anchor inserted therein are required. This not only saves time but also reduces labor costs when compared to more complicated anchoring systems. In cases where there is little room or if complex steelwork is involved, the anchor can be placed in alternative holes to avoid interference.

5. Reduced Risk of Damage to Concrete

The traditional lifting systems usually have big stresses on the concrete to the point that it can produce cracks or spalling. Hairpin anchors were designed to attempt to eliminate this problem. The castellations protect the concrete during the lifting process by reducing ring clutch rotation and transferring lateral forces directly to the edge of the anchor.

BaoQi: Your Reliable Partner for High-Quality Hairpin Anchors

BaoQi, a company with over a decade of experience in producing high-quality forging, casting, and punching parts, specializes in manufacturing hairpin anchors that meet and exceed international standards. As a member of SMETA and certified under ISO 9001, BaoQi’s commitment to quality assurance is unmatched. Their manufacturing facilities are equipped with state-of-the-art technology, enabling them to produce customized, durable hairpin anchors suitable for a wide range of construction applications.

BaoQi hairpin anchors are designed for maximum efficiency, with safety and reliability for the clients being ensured. They are particularly high-lighted for their resistance to high lifting capacities, which enables them to undertake even the most complicated construction and civil engineering projects. Besides, the anchors from BaoQi are hot-dipped galvanized to resist corrosion for a long period, something of great importance in maintaining structural integrity and safety in the whole construction project.

Furthermore, BaoQi’s expert team provides tailored solutions, working closely with clients to design and deliver hairpin anchors that meet specific project requirements. Whether the need is for bespoke designs or specialized configurations, BaoQi’s engineers offer invaluable support, ensuring optimal performance for every project.

Global Reach and Sustainability in Construction

BaoQi dedicates equal amounts of energy toward quality and innovation, extending into the entire scale of products manufactured. Currently, their international client list includes companies operating in Australia, Denmark, Finland, France, Germany, the UK, the US, Canada, and many Middle Eastern nations. Meanwhile, the company keeps integrating greener practices into the scope of operations-a factor further building sustainability into modern construction.

Conclusion: Why Hairpin Anchors Are Important

These types of anchors provide modern construction with an increase in lifting capability and safety, adding durability. That they can take up heavy loads, reduce the damage to the concrete, and ease of installation makes them useful in a broad range of activities from precast concrete lifting, civil engineering projects, and projects at offshore venues. Construction projects have become so complex and their safety requirements very high that a need was felt for a solution that could withstand these pressures-hairpin anchors.

When performance, reliability, and durability for hairpin anchors are in need of superior lifting capacity and longevity, BaoQi is a partner you should rely on.