When it comes to structural integrity and stability in construction, anchor plates play an indispensable role. As essential components in various building and engineering projects, understanding their functions, applications, and benefits can provide valuable insights to professionals and enthusiasts alike. This article delves deep into what anchor plates are used for, the types available, their applications, and the materials commonly employed.

Overview of Anchor Plates

Definition and Basic Function

Anchor plates, also known as wall anchor plates or tie plates, are flat, typically rectangular or circular metal components. They serve the primary function of distributing load and providing structural reinforcement. By securing different elements of a construction, anchor plates ensure that the structure withstands various forces and stresses, maintaining its integrity over time.

Anchor plates are often associated with masonry walls, where they help to stabilize the structure by countering lateral loads and preventing outward movement. Their application is not limited to masonry, however, as they are likely to be an integral part of steel structures, retaining walls, and other critical construction components.

Historical Background

Historically, anchor plates have been employed for centuries, with their use dating back to medieval times. Early examples can be found in half-timbered houses and historic buildings, where wrought iron anchor plates were used to secure wooden beams and prevent the walls from bulging outward. Over time, the design and materials of anchor plates have evolved, but their fundamental purpose—reinforcing structures and ensuring stability—remains unchanged.

Types of Anchor Plates

Standard Anchor Plates

Standard anchor plates are pre-fabricated in common sizes and shapes to cater to a wide range of applications. These include rectangular, circular, and star-shaped designs, often made from durable materials like steel. The versatility of standard anchor plates makes them suitable for various construction scenarios, from residential buildings to large infrastructure projects.

These plates are typically produced to meet industry standards and regulations, ensuring their effectiveness in providing structural support. The ease of installation and availability of standardized options make these anchor plates a popular choice among engineers and builders.

Customized Anchor Plates

While standard anchor plates suffice for most applications, some projects demand bespoke solutions. Customized anchor plates are designed and fabricated to meet specific requirements, considering factors such as load specifications, architectural design, and material compatibility. These plates often cater to unique structural challenges, such as irregular shapes or sizes, distinct aesthetic requirements, or specific load-bearing needs.

The customization process involves collaboration between engineers, architects, and fabricators to create anchor plates that meet exact project specifications. This tailored approach ensures that the anchor plates provide the required support and stability, despite the complexities of the individual construction project.

Applications in Construction

Structural Support

One of the primary applications of anchor plates is providing structural support. By connecting and reinforcing different elements within a building, these plates help ensure that the overall structure can handle various loads and stresses. For instance, in multi-story buildings, anchor plates are crucial in tying floors and walls together, preventing any displacement caused by external forces such as wind or seismic activity.

Anchor plates also enhance the structural integrity of retaining walls and bridges, offering a secure connection between the different components. This application is particularly important in preventing collapse and ensuring long-term stability.

Earthquake Resistance Mechanisms

In regions prone to seismic activity, anchor plates play a vital role in earthquake resistance mechanisms. By distributing seismic forces throughout the structure, these plates help absorb and mitigate the energy generated during an earthquake. This prevents catastrophic structural failure and enhances the building’s resilience.

Specialized anchor plates designed for seismic applications often incorporate flexible elements that allow controlled movement and energy dissipation. These innovative designs contribute to safer buildings and infrastructures in earthquake-prone areas.

Architectural Aesthetics

While anchor plates primarily serve a functional purpose, they can also contribute to the architectural aesthetics of a structure. In historic buildings, for example, anchor plates often feature decorative designs that complement the overall architectural style. Modern constructions also utilize aesthetically pleasing anchor plates, blending structural functionality with visual appeal.

Architects and designers often work closely to integrate anchor plates into the building’s design, ensuring that they enhance rather than detract from the visual appearance. This dual function of providing support and enhancing aesthetics underscores the versatility of anchor plates in construction.

Materials Used in Anchor Plates

Steel and Its Properties

Steel is the most commonly used material for anchor plates due to its exceptional strength, durability, and versatility. The material’s high tensile strength allows it to bear significant loads without deforming or failing, making it ideal for structural support applications. Additionally, steel is resistant to various environmental factors, including temperature fluctuations and moisture, which ensures the longevity of anchor plates.

Different types of steel, such as galvanized steel, are often used depending on the specific requirements of the application. Galvanization provides an added layer of protection against corrosion, further extending the lifespan of steel anchor plates in harsh environments.

Alternative Materials and Their Benefits

While steel remains the material of choice, alternative materials such as aluminum and composite materials are also employed in certain applications. Aluminum, for instance, offers the benefit of being lightweight and corrosion-resistant, making it suitable for specific structural uses where weight reduction is crucial.

Composite materials, made from a combination of fibers and resin, provide strong yet lightweight alternatives to traditional materials. Their customization capabilities and resistance to various environmental conditions make them a viable option for modern constructions looking for advanced engineering solutions.

Installation Techniques

Preparation and Planning Stages

The successful installation of anchor plates begins with thorough preparation and planning. This involves assessing the structure’s requirements, determining the correct size and type of anchor plates needed, and ensuring that all materials and tools are available. Detailed planning helps to avoid potential issues and ensures that the installation process runs smoothly.

Engineers and contractors will typically conduct a site survey to evaluate the existing structure and identify the optimal placement for anchor plates. This stage is critical for ensuring that the plates will provide the necessary structural support and stability.

Tools and Equipment Required

Proper installation of anchor plates necessitates the use of specific tools and equipment. Basic tools such as drills, hammers, and measuring tapes are essential, along with more specialized equipment like torque wrenches and hydraulic jacks.

Safety Gear

Safety gear is paramount to protect workers during the installation process. This includes hard hats, safety goggles, gloves, and steel-toed boots to prevent injuries from falling debris, sharp edges, and heavy materials.

Specialized Tools

Specialized tools such as impact drivers, power drills, and welding machines may be used depending on the type of anchor plate and the method of attachment. These tools ensure precise installation, helping to secure the plates effectively and safely.

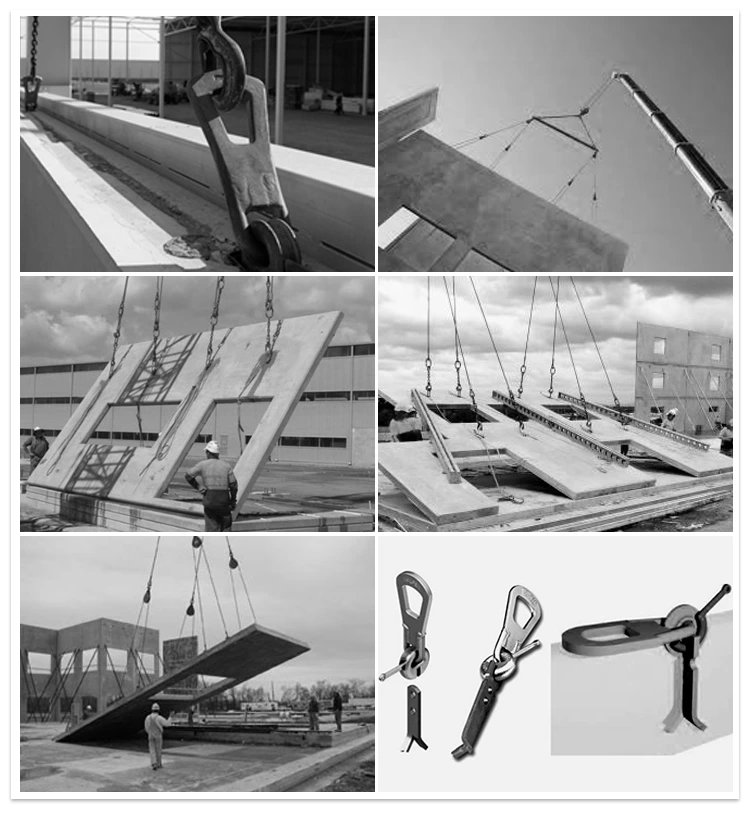

Step-by-Step Installation Process

The installation of anchor plates involves several steps, starting with marking the locations where the plates will be installed. Next, holes are drilled into the wall or structural element at the marked positions. The anchor plates are then aligned with these holes and secured using bolts or welding techniques, depending on the design and material.

Once the anchor plates are in place, they are tightened to the required specifications to ensure a secure fit. The final step involves inspecting the installation to ensure that the plates are properly positioned and securely attached.

Advantages of Using Anchor Plates

Durability and Strength

Anchor plates are known for their durability and strength, making them a reliable choice for reinforcing structures. Steel anchor plates, in particular, offer exceptional load-bearing capacity and resistance to environmental stresses, ensuring long-term stability and safety.

Cost-Effectiveness

Despite their robust construction, anchor plates are cost-effective solutions for structural reinforcement. Their long lifespan and minimal maintenance requirements translate to lower costs over time, making them an economical option for both small and large construction projects.

Versatility Across Various Structures

Anchor plates are highly versatile and can be used across a wide range of structures, from residential buildings to commercial and industrial complexes. Their ability to adapt to different construction techniques and materials makes them a valuable component in diverse architectural and engineering applications.

Possible Challenges and Solutions

Common Installation Issues

While anchor plates offer numerous benefits, their installation can present challenges that need to be addressed to ensure optimal performance.

Misalignment Problems

Misalignment during installation can compromise the structural integrity of the anchor plates. This issue can be mitigated by careful planning and precise measurement during the preparation stage.

Corrosion Risks

Corrosion is a common concern, particularly for metal anchor plates exposed to harsh environmental conditions. Using materials like galvanized steel or applying protective coatings can help prevent corrosion and extend the lifespan of the anchor plates.

Load-Bearing Concerns

Ensuring that anchor plates are capable of bearing the intended loads is critical. This can be achieved by selecting the appropriate size and material for the anchor plates, based on a thorough assessment of the structure’s requirements.

Maintenance and Inspection

Regular Maintenance Practices

Maintaining anchor plates involves regular cleaning and inspection to identify and address potential issues before they become serious problems.

Cleaning Procedures

Routine cleaning helps to remove dirt, debris, and other contaminants that can cause corrosion or weaken the anchor plates. This can be done using brushes, water, and mild cleaning agents.

Protective Coatings Application

Applying protective coatings, such as paint or corrosion inhibitors, can provide an additional layer of protection against environmental factors, enhancing the durability of the anchor plates.

Routine Inspection Checklist

Regular inspections are essential to ensure that anchor plates remain in good condition. This includes checking for signs of wear and tear, corrosion, and any structural movement that could affect the performance of the anchor plates.

Role in Modern Engineering Projects

Innovations in Design and Usage

The field of construction constantly evolves, and so do the designs and applications of anchor plates.

Smart Anchor Plates

Innovations in smart materials and technology have led to the development of smart anchor plates, which can monitor structural health in real time. These advanced plates are equipped with sensors that detect stress, movement, and other critical parameters, allowing engineers to proactively address potential issues and enhance the safety and longevity of structures.

Summary Remarks on Anchor Plates

In summary, anchor plates are vital components in construction, offering unparalleled structural support, durability, and versatility. With varied applications ranging from earthquake resistance to architectural aesthetics, these plates play a crucial role in modern engineering projects. By understanding their uses, benefits, and proper installation techniques, builders and engineers can harness the full potential of anchor plates to create safer, more stable, and aesthetically pleasing structures.

BAOQI Anchor Plates are high-quality construction components designed to provide secure and reliable anchoring solutions. These plates are commonly used in various construction projects, including the installation of steel structures, concrete walls, and other heavy-duty applications.

BAOQI Anchor Plates are made from durable materials such as steel or stainless steel, ensuring their strength and longevity. They are designed with multiple holes or slots to accommodate different types of fasteners, allowing for flexibility in installation.

These anchor plates are easy to install and provide a strong connection between the structure and the foundation. They help distribute the load evenly, preventing any potential structural failures or damage. BAOQI Anchor Plates are also resistant to corrosion, ensuring their performance and reliability even in harsh environments.

With their high-quality construction and reliable performance, BAOQI Anchor Plates are trusted by professionals in the construction industry worldwide. They are an essential component for ensuring the stability and safety of various structures, making them a preferred choice for architects, engineers, and contractors.

In summary, BAOQI Anchor Plates are durable, easy to install, and provide a secure anchoring solution for various construction applications. Their high-quality construction and reliability make them a trusted choice for professionals in the industry.