Lifting heavy loads safely and efficiently is an important aspect of industries such as construction, manufacturing, and maritime transport. Among the many tools designed to secure loads during lifting operations, the lifting eye anchor plays a pivotal role in ensuring safety and stability. The selection of the proper material for such components can have a direct impact on the success of the lifting operation, anything from the ability of the anchor to carry out its load-carrying task to its lifetime under harsh environmental conditions. Material varieties used for the making of the lifting eye anchors, key factors to consider when selecting one, and how BaoQi ensures quality, dependable lifting eye anchors to industry demands are reviewed in this paper.

Why Material Selection Matters in Lifting Eye Anchors

Lifting eye anchors are subjected to huge tensile forces, vibrations, and environmental stresses-all must be taken into consideration during material choice. The wrong material can lead to premature wear, failure, or even catastrophic accidents; this decision is critical.

According to industry reports, such as those by Markets and Markets, material innovation remains key in the lifting equipment industry, and the global manufacturing of lifting equipment is set to grow at a CAGR of 4.8% through 2028, buoyed by increasing safety standards and advances in materials science.

Understanding Components of Lifting Eye Anchors

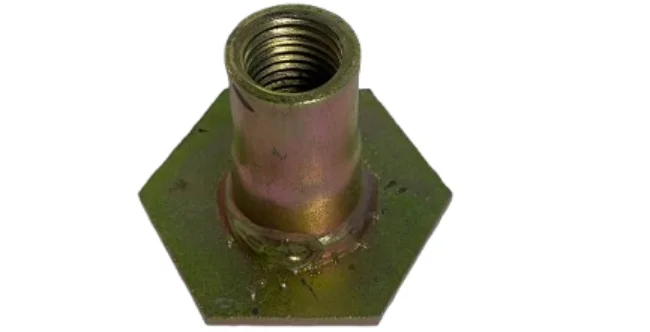

Before discussing further the best material for lifting eye anchors, it will be important to understand what actually constitutes the components of the device. These anchoring devices have basically two parts :

Lifting Eye: In general, the feature is available for connecting a hook or sling device for lifting purposes; designed to present an easy facility for engagement/disengagement that avoids damage not only to itself but also the equipment and/or anchor.

The anchor portion is the means that attaches the lifting system to a structure or load. It can either be bolted into concrete or embedded in a structural unit during manufacturing. Material: In the anchor, material resistance should be able to resist tension and shear forces, and hence it is very important for durability and safety.

Now, let us take a look at the common materials used to manufacture the lifting eye anchor and what makes them suitable for those very critical tasks.

1. Carbon Steel: The Heavy Lifting Standard

Due to a great ratio of strength versus weight, along with being cost-effective, carbon steel finds extensive use in the fabrication of lifting eye anchors. These are usually manufactured from AISI 1045 and AISI 1060 Carbon Steel for other lifting equipment pieces, such as the making of a lifting eye and anchors. It’s a robust material featuring a high level of tensile strength, thus serving well in very heavy load operations related to industry sectors.

The advantages of carbon steel in the lifting application are many. It is:

- Economical:Carbon steel tends to be less costly than other high-strength alloys.

- Tough:With a high tensile strength, it can resist extreme forces involved with lifting operations.

- Versatile:It is highly adaptable and can be forged, welded, or machined to produce a wide range of anchor designs.

However, carbon steel has certain disadvantages for working in a corrosive environment, such as in a sea or chemical enterprise, because it gets rusty after a specific time period. To complement that, BaoQi uses various procedures like the inclusion of coatings or galvanization for strengthening the steels against corrosion resistance.

2. Stainless Steel: For Corrosive Environments

When lifting operations are carried out in marine, chemical, or outdoor environments, the possibilities of rust and corrosion are very high, and that is where stainless steel comes into play. Stainless steel is mainly resistant to rust, oxidation, and staining, especially grades 304 and 316, making them perfect for usage in moist, chemical, or salty environments.

BaoQi’s Lifting Eye Anchors made from stainless steel offer numerous advantages for industries in need of corrosion-resistant solutions, including:

- Superior Durability: Stainless steel has a longer lifespan compared to other materials, even in harsh conditions.

- Resistant to Corrosion: The chromium content in stainless steel creates a protective oxide layer, making it highly resistant to rust.

- Aesthetic Appeal: Stainless steel has a polished, clean finish that is ideal for applications where appearance matters.

Stainless steel is widely used in maritime, chemical manufacturing, and food processing industries for lifting operations under conditions that require strong, non-corrosive materials.=

3. Alloy Steel: The Choice for Extreme Loads

Alloy steel is used in applications that require super high load-bearing capacities. Consequently, alloy steels such as 4140 and 4340 are heat-treated to achieve an optimum combination of strength, toughness, and resistance to wear. These steels are alloyed with elements like chromium, molybdenum, and nickel for improved mechanical properties that make them suitable for applications involving high-stress lifting. Some of the advantages of alloy steel in lifting eye anchors include:

- Enhanced Strength:These steels are specifically designed to resist deformation under extreme loads, making them suitable for high-tensile applications. · Improved Toughness: Alloy steels maintain their integrity in harsh conditions, including high-impact environments.

Fatigue Resistance: Alloy steels are less likely to fail under repeated loading and unloading cycles, ensuring long-term reliability.

It makes alloy steel the metal of choice in heavy lifting at industries that include but are not limited to construction, mining, and oil & gas. Lifting eye anchors from BaoQi in alloy steel will be just apt for anchoring large precast concrete structures, heavy machinery, and several others.

4. Forged Steel: Precision and Strength

It contains forged steel when precision with strength is to be required. Because the forging of steel under the high pressure reshapes the inside grain structure in the material to make it harder and more enduring than cast steel, BaoQi specializes in forging lifting eye anchors. These would bring definite advantages in high-strength requirements and precision on size control.

Benefits regarding forged steel found in lifting eye anchors include the following:

- Mechanical Properties:Forging makes the steel tough and resistant to wear and tear; therefore, its applications are popular where demands are greater and much greater.

- Precision Design:The forging process allows for tighter tolerances and more precise manufacturing of lifting components.

- Long Life: Generally, the life of forged steel components is longer as they resist stress and fatigue.

Forged steel lifting eye anchors find great applications in heavy-duty lifting industries: construction, marine, and energy.

BaoQi High-Quality Lifting Eye Anchors: Your Trustful Partner

With more than 10 years of experience in manufacturing lifting eye anchors, BaoQi produces its products using carbon steel, stainless steel, alloy steel, and forged steel, providing top-quality products with a high degree of strength. BaoQi, certified to ISO-9001 standards, guarantees the quality of each lifting eye anchor by adhering to rigorous quality control, which includes safety, durability, and performance.

The Cross Hole Lifting Anchors by BaoQi, on the other hand, are all about precasting large units such as slabs, beams, and even pipes, reflecting the company’s commitment to quality and innovative products. These anchors will be specifically engineered for lifting purposes with a safety factor of 3 against breakage. Fittings are CE-marked and delivered with 3.1 certificate; thus, one is guaranteed that they meet international standards.

Conclusion: Choice of Material – Lifting Eye Anchors

A combination of strength, durability, and resistance against environmental elements will make a very suitable material selection for a lifting eye anchor. This ranges from carbon steel, stainless steel to alloy, forged steel. Your material selection needs to match up to the application that is involved within your particular industry.

From general steel to lifting eye anchors, BaoQi can provide customers with various kinds of options designed in accordance with high industry standards. Having a great concentration on ISO-certified manufacturing processes, BaoQi is one of the reliable business partners in securing and lifting solutions for the global market.