When handling and moving heavy weights in industry, construction, and engineering use, strength and safety are paramount. The choice of the right lifting mechanism—the lifting socket or hook—can make or break your operation’s success and safety. While both lifting sockets and hooks are ubiquitous across all industries, each has its advantages and disadvantages.

Understanding the Basics: Lifting Sockets vs. Hooks

Hooks for Lifting: Hooks have been used in lifting operations since centuries. They are used in hoists, cranes, and lifting chains to connect the lifting device with the load. Made of high-strength steel alloys, lifting hooks are inexpensive, uncomplicated, and versatile. The open-ended structure of hooks would, however, require additional safety devices such as safety latches to prevent premature release of the load.

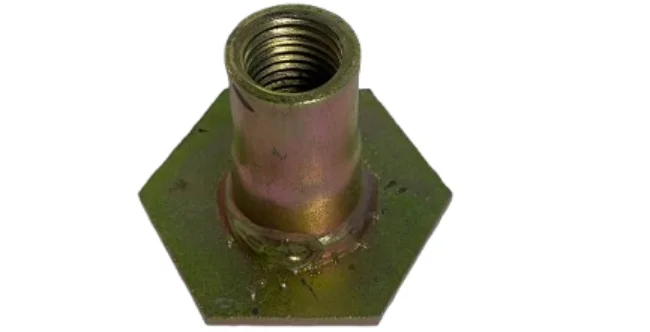

Lifting Sockets: Lifting sockets, on the other hand, are integrated units designed to provide a safe and stable point of lifting connection. They provide first-time use in the building and heavy machinery sectors for lifting and re-location of heavy loads such as concrete panels, steel beams, and equipment in a safe and sound manner. Lifting sockets, unlike hooks, are usually placed into the structure or into the load itself in an effort to provide a more intrinsic and safer connection.

Strength and Durability: Which Is More Reliable for Heavy Loads?

Lifting solutions under consideration, strength and durability concerns cannot be eluded. Both lifting sockets and hooks need to be strong enough to resist lifting heavy loads stresses. However, their design and material affect overall performance.

Lifting Hooks: Strong but Application-Limited

Hooks are usually made of high-strength steel in order to sustain heavy loads. The strength depends on the quality of the material, fabrication technique, and hook size. By way of illustration point, an off-the-shelf hook may only be able to support a few tons to several dozen tons of load, depending on usage.

But the limit of the strength performance of the hook is also controlled by the way that the hook is required to look. Since hooks are premised on metal strength to withstand loads at a point, hooks tend to be worn out at contact points, especially where dynamically shaped or unshaped loads are involved. Besides, the openness of the hook, as very flexible, has a tendency to cause instability, especially while transacting in oblique directions or side loads. This renders them more susceptible to deformation of the hook, compromising its strength and overall lifespan.

Lifting Sockets: Increased Strength and Stability

Sockets for lifting, especially those manufactured by companies like BaoQi, are crafted using high-strength material such as carbon steel or zinc alloy to provide optimum strength and load-carrying capacity. The Precast Zinc Flat Cast-in Lifting Fixing Socket by BaoQi is built to handle heavy tensile and compressive loads, making it a perfect option for heavy lifting in building and industrial applications.

Safety Features: Which Provides Better Protection?

Safety first while handling heavy loads. Equipment lifted negligently can result in catastrophic consequences, including damage, loss of lives, and huge loss of property. Now let us analyze the safety aspect of lifting hooks and sockets.

Safety Features of Lifting Hooks

Although a plain and commonplace lifting device is the hook, its open framework has several issues related to safety. One of the most common issues is the potential for the load to fall off the hook, especially if it is not properly secured. To mitigate this risk, most hooks have safety latches or locks that will keep it from releasing accidentally. These mechanisms do degrade over time and may not entirely eliminate the risk of failure under heavy loads or in high-risk applications.

Safety Benefits of Lifting Sockets

Lifting sockets offer a much higher level of safety, as they are designed to be securely embedded within the load or structure. This integration ensures a much more stable lifting point, eliminating the risk of accidental release or instability during lifting. BaoQi’s Precast Zinc Flat Cast-in Lifting Fixing Sockets are built with precise engineering to ensure that they are securely positioned during installation, significantly reducing the risk of slippage or failure during the lifting process.

Lifting Socket vs. Hook: Which is More Suitable to Some Applications?

Though both hooks and lifting sockets are handy, the decision depends mainly on the application and requirements of the lifting task.

Construction Projects

In construction projects, lifting sockets are usually applied as a more favorable choice of being stronger and more stable. When lifting heavy loads such as concrete beams, walls, or large equipment, lifting sockets create a more and more stable connection compared to hooks. Straight Bar Lifting Sockets of BaoQi, for instance, are designed to lift heavy concrete parts and steel beams without flexing or bending, distributing the load evenly, reducing structural damage.

Material Handling and Manufacturing

For material handling and manufacturing applications, lifting hooks can be adequate for lighter to medium loads. But for precision settings or for hoisting large industrial machinery, lifting sockets are safer and more durable and therefore the preferred option.

Transportation and Logistics

Lifting sockets are also widely applied in the logistics industry to transport heavy loads or equipment because they can carry more weight and endure wear and tear. BaoQi Lifting Sockets are utilized to form a safe connection between oversized loads like wind turbine blades or huge building materials so that they can be transported efficiently with minimal risk.

BaoQi: A Leader in Lifting Socket Solutions

For companies seeking stable and compliant lifting socket manufacturers, BaoQi is a familiar name. As one of the established manufacturers with over 10 years of experience in exporting lifting systems, BaoQi strives to deliver top-quality, safe, and long-lasting lifting equipment. Every lifting socket they manufacture is tested according to an ISO-9001 standard to ensure global quality and performance standards compliance.

BaoQi manufactures a range of lifting sockets for various construction, transportation, and energy applications. Its Precast Zinc Flat Cast-in Lifting Fixing Sockets and Straight Bar Lifting Sockets can endure extremely heavy loads, corrosion resistance, and durability. With four state-of-the-art plants and customer satisfaction in mind, BaoQi is the ideal business partner for enterprises that seek to maximize the efficiency and safety of their lifting processes.

Conclusion: Selecting the Appropriate Solution for Your Lifting Needs

In summary, though there is a use for lifting hooks and lifting sockets, lifting sockets are stronger, steadier, and safer generally speaking, especially where heavy construction, industrial, and factory plant lifts are involved. Their neat self-contained construction, protection from corrosion, and ability to accommodate high loads are key reasons lifting sockets are best for most dangerous lifts.