Understanding the Use of Lifting Sockets in Precast Construction

Importance of Lifting Sockets

Lifting sockets are essential in the realm of precast concrete construction. They function as the pivotal connection points for lifting equipment, which is vital for the safe and efficient handling of heavy precast elements. Improper installation and use of lifting sockets can compromise the structural integrity of the concrete elements, potentially leading to accidents or damage during lifting operations. These sockets provide a dependable method for managing precast concrete, ensuring that all lifting procedures are conducted safely and effectively.

Common Applications in Precast Concrete

Lifting sockets are widely used in various applications within the precast concrete industry. They are often employed in the construction of walls, beams, and columns, where precise positioning and secure handling are mandatory. Additionally, lifting sockets are integral to the process of manufacturing concrete slabs and panels, where they ensure that these large elements can be transported and installed safely. Their versatility and reliability make them an indispensable component in many precast concrete projects.

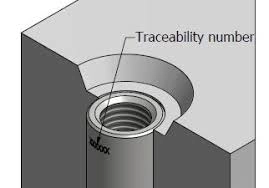

Introduction to Baoqi Products

Baoqi Products offers a range of innovative solutions for the precast concrete industry, including high-quality lifting sockets. Known for their durability and precision, Baoqi’s lifting sockets are designed to meet the rigorous demands of construction projects. These products undergo stringent quality control measures to ensure they perform effectively under various conditions. By integrating Baoqi’s lifting sockets into your precast construction processes, you can enhance both safety and efficiency.

Procedures for Lifting Precast Elements with Sockets

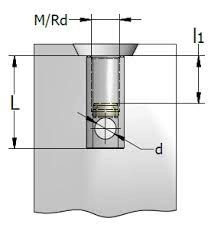

Assessing the Load and Choosing the Right Socket

Before initiating any lifting operation, it’s essential to assess the load accurately and choose the appropriate lifting socket for precast elements. This involves calculating the weight of the precast component and understanding its dimensions and shape. Selecting the right socket ensures that the lifting operation can be performed securely without risking damage to the element or failure of the lifting mechanism. This preliminary step is foundational to a successful and safe lifting process.

Preparing the Precast Element

Preparation of the precast element is a critical phase. This step includes verifying the correct installation of lifting sockets and ensuring that the concrete surrounding these sockets has completely cured. Any debris or irregularities near the socket must be removed to enable a seamless lifting operation. Checking these conditions is essential to avoid unexpected problems during lifting, thereby protecting both the workers and the precast elements.

Steps for Safe Lifting

Ensuring Secure Connection

Establishing a secure connection between the lifting socket for precast elements and the lifting equipment is paramount. This involves double-checking that all components are firmly connected and properly aligned. Any loose connections or misalignments should be rectified before commencement. Only when the connection is secure can the lifting operation proceed safely.

Using Appropriate Lifting Equipment

Using the right lifting equipment is essential for a successful lifting operation. This includes cranes, slings, and shackles designed to handle the specific weight and configuration of the precast element. Ensuring that the equipment is suitable and in good condition minimizes the risk of accidents and enhances the overall efficiency of the lifting process. Regular maintenance and inspection of lifting equipment also play a significant role in maintaining safety standards.

Safety Measures During the Lifting Process

Training and Expertise Requirements

Proper training and expertise are critical components in ensuring the safety of lifting operations involving precast elements. Workers should be trained in both the technical aspects of using lifting sockets and the overall safety protocols. This includes understanding load calculations, socket installation, and equipment operation. Continuous training and upskilling ensure that workers are well-prepared to handle the challenges of lifting operations.

Inspection and Maintenance of Equipment

Routine inspection and maintenance of lifting equipment are crucial for ensuring safe lifting operations. This includes periodic checks to identify wear and tear, confirming that every component is operating correctly. It’s essential to adhere strictly to maintenance schedules, and any defective equipment must be promptly repaired or replaced. Regular inspection and maintenance routines are key to preventing equipment malfunctions and accidents during lifting activities.

Risk Management Strategies

Identifying Potential Hazards

Identifying potential hazards is a proactive approach to preventing accidents during the lifting process. This includes recognizing factors like unstable ground conditions, improper load distribution, and environmental conditions that could affect the lifting operation. By understanding and identifying these hazards beforehand, preventative measures can be put in place to mitigate risks effectively.

Implementing Safety Protocols

Implementing comprehensive safety protocols is essential for protecting workers and ensuring smooth lifting operations. These protocols should include guidelines for the proper use of lifting sockets for precast, emergency procedures, and the use of personal protective equipment (PPE). Adhering to established safety protocols minimizes the risk of accidents and enhances the safety and efficiency of the lifting process. Regular safety drills and audits can further reinforce these protocols, ensuring a culture of safety within the workplace.

Advantages of Using Quality Lifting Sockets from Baoqi

Material Strength and Durability

One of the primary advantages of using lifting sockets from Baoqi is their superior material strength and durability. These sockets are manufactured from high-grade materials that ensure longevity and robustness under heavy loads. The exceptional tensile strength of Baoqi lifting sockets makes them ideal for handling the substantial weights often involved in precast concrete elements. This reliability reduces the risk of socket failure and contributes to the overall safety and efficiency of lifting operations. Additionally, the durability of Baoqi lifting sockets means they can be reused across multiple projects, offering cost savings over time.

Compliance with Industry Standards

One notable advantage of opting for Baoqi lifting sockets is their adherence to rigorous industry standards. Baoqi’s products are crafted and produced in accordance with both international and local regulations, ensuring their safety and dependability for users. Observing these standards is essential for any construction endeavor as it guarantees that the lifting equipment can endure the demands and stresses experienced during operation. This compliance also signifies that the lifting sockets undergo thorough testing, offering assurance that they will function as anticipated in various working conditions. Utilizing lifting sockets that conform to industry standards is instrumental in preserving the integrity of the construction process and preventing potential legal and safety complications.

Customer Support and Service

Baoqi not only provides quality lifting sockets for precast concrete but also offers exceptional customer support and service. This includes technical assistance for selecting the right type of lifting socket for specific project requirements, as well as after-sales support for product maintenance and troubleshooting. Baoqi’s commitment to customer service ensures that clients receive comprehensive guidance throughout their projects, from procurement to the execution phase. Having access to expert advice helps construction professionals resolve any uncertainties quickly and effectively, contributing to smoother project workflows and enhanced safety measures.

Conclusion: Enhancing Safety and Efficiency in Precast Construction

In conclusion, the use of quality lifting sockets for precast concrete elements is fundamental to the success of construction projects. By integrating robust and durable lifting sockets, like those offered by Baoqi, construction professionals can ensure the safety and efficiency of their lifting operations. The importance of selecting the right lifting socket cannot be overstated, as it directly impacts the structural integrity and handling of precast elements. Adhering to proper procedures, including load assessment, equipment preparation, and rigorous safety protocols, further enhances the outcomes of these operations. Ultimately, investing in high-quality lifting sockets and a thorough understanding of their applications and safety measures not only safeguards the workforce but also contributes to the seamless execution of construction projects.