In the construction and infrastructure industries, the efficiency and safety of lifting equipment are critical to project success. Lifting loops and chain hoists are two of the most commonly used tools for lifting heavy loads, especially in the handling of precast concrete components. However, when comparing their cost-effectiveness, there are numerous factors that businesses must consider, such as initial investment, operational efficiency, safety, maintenance, and versatility.

For businesses that are looking for reliable lifting solutions, understanding the differences between lifting loops and chain hoists can be very helpful in making an informed choice.

Lifting Loops: A Flexible and Efficient Solution

Lifting loops are a popular choice for handling precast concrete components, as well as other heavy, bulky materials. Wire rope lifting loops, in particular, are designed to provide a flexible, durable, and safe lifting point that allows construction workers to lift and move precast elements with precision. Lifting loops are typically embedded within concrete structures or added to products as a permanent lifting point.

Key Advantages of Lifting Loops

1. Cost-Effectiveness in the Long Run.

The upfront cost of acquiring lifting loops might seem low, but the cost-effectiveness over time is beyond dispute. The lifting loops are meant for heavy-duty use and longevity; they rarely need replacement or maintenance, thereby contributing to lower TCO.

According to the report by the Construction Industry Institute, the total cost of lifting operations can be reduced by up to 20% when using lifting loops instead of other lifting solutions, such as cranes or chain hoists. Their reusability across multiple lifting operations further reduces costs, making them a very economical choice for large-scale construction projects.

2. Safety and Stability

Lifting loops have been designed with safety features aimed at firmly securing the loads to the lifting point, and consequently reducing slippage or detachment during operations. This increases the security of the operators and minimizes possible accidents or material damages. They can be manufactured with high-strength materials like galvanized steel or stainless steel, so that the loops can always be strong enough to resist pressures while providing a secure attachment.

A study published by Safety and Health in Construction emphasizes that safety is a leading concern on construction sites, and the use of equipment like lifting loops that reduce the risk of accidents can lead to fewer insurance claims, fines, and downtime.

3. Flexibility and Versatility

Lifting loops are very adaptable. They function with a large variety of lifting equipment, such as slings, chains, and hooks, in almost any conceivable way that one might design a lift for any number of configurations. Their high tensile strength means they can also lift beams, panels, and slabs, among other types of precast concrete elements, both in vertical and horizontal positions.

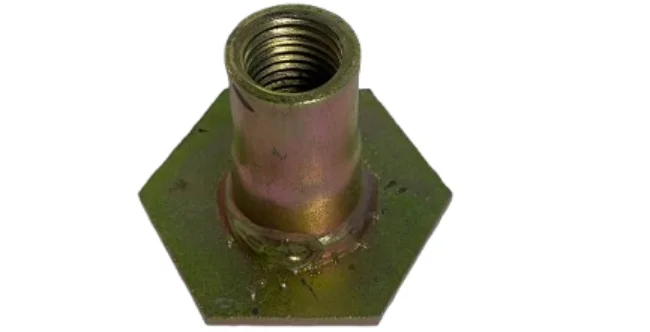

BaoQi Tech’s Wire Rope Lifting Loops, for example, are specifically designed to provide efficient lifting for precast concrete units and are compatible with threaded lifting inserts. This flexibility allows businesses to streamline their operations, handling a range of materials with the same lifting equipment, which further reduces operational costs.

Real-World Use Case: Precast Concrete Handling

A case study from a major construction project in the U.K. found that switching from traditional chain hoists to wire rope lifting loops for handling precast concrete panels resulted in a 15% reduction in overall labor costs. The combination of faster lifting times, fewer safety incidents, and a reduction in equipment downtime directly contributed to significant cost savings for the company.

Chain Hoists: The Heavy Lifting Standard

Key Advantages of Chain Hoists

1. Control and Precision

One of the key advantages of chain hoists is the level of control they offer during lifting operations. Chain hoists allow operators to lift loads slowly and with precision, which is particularly useful in situations where the load needs to be positioned accurately, such as in assembly lines or for moving heavy machinery.

According to a report by Hoist & Crane, chain hoists are often used in situations where precision in load placement is critical. This makes them ideal for applications in manufacturing and assembly operations where the weight of the load is consistently managed.

2. Robust Lifting Power

Chain hoists have manual and electric setups. Electric types are used as they can bear heavy loads compared to the amount of human exertion needed and are commonly employed in heavy manufacturing, like automobiles and steel production; in construction works, lifting massive concrete elements also; it suits for both indoor or outdoor applications under even the hardest environment.

3. Costly to use when the need only is for the short term period.

For shorter term or intermittent lift work, chain hoists are likely to be cheaper. Hand chain hoists, in particular, are not too pricey and range from a few hundred dollars based on the capacity. Still, the operating and maintenance cost for using such devices over time will pile up, especially with electric types, which will require constant maintenance and potentially more power consumption.

Heavy Machinery Handling Example in Practice

A manufacturing plant in Germany used electric chain hoists to handle large machinery and equipment weighing several tons. Although the initial investment in the hoist system was higher, the ease of control and precision achieved with the electric chain hoist allowed for more efficient handling of the machinery. The plant reduced labor costs and minimized the risk of machinery damage during lifting. However, when it came to lifting large concrete panels for construction, they found that lifting loops were more cost-effective due to their lower maintenance and versatility.

Lifting Loops vs. Chain Hoists: The Cost-Effectiveness Analysis

When evaluating the cost-effectiveness of lifting loops vs. chain hoists, several factors must be considered:

- Initial Investment: The upfront cost of chain hoists, especially electric models, is quite high. However, larger-scale or even continuous lifting jobs can justify using electric chain hoists due to their durability and strength. Lifting loops, by contrast, can be relatively low in procurement, especially for business enterprises that primarily deal with handling precast concrete.

- Labour and Operational Efficiency: Lifting loops are engineered to make lifting processes more efficient with less labor hours and minimal readjustments by operators. This translates to lesser labor hours in operations as compared to chain hoists, which typically demand more people for safe operation. Businesses engaged in construction or infrastructure would find that lifting loops are their most economical choice with regard to operational efficiency.

- Maintenance and Longevity:Chain hoists, particularly electric models, require regular maintenance, including servicing of electrical components and chain lubrication. In contrast, lifting loops, such as BaoQi’s Wire Rope Lifting Loops,are designed for durability and require minimal maintenance. Their robust construction ensures they can be used for a long time, reducing maintenance costs.

- Safety: Safety must always be a prime concern on any construction site. Lifting loops provide secure attachment points, and therefore, they minimize the risks associated with accidents during lifting operations. Chain hoists also provide safety benefits but not always to the same level as security in the lifting point and overall load management.

Conclusion: Which One Is More Cost-Effective?

In conclusion, while both lifting loops and chain hoists offer valuable benefits, the choice between the two ultimately depends on your specific lifting needs and the nature of your operations. Lifting loops, particularly Wire Rope Lifting Loops from BaoQi Tech, offer superior cost-effectiveness for large-scale construction projects, especially when dealing with precast concrete elements. They provide a durable, safe, and efficient solution that can significantly reduce long-term operational costs.

Chain hoists are good for smaller or precision-based lifts, but if cost-effectiveness is considered in terms of larger construction or infrastructure projects, lifting loops are the better option.