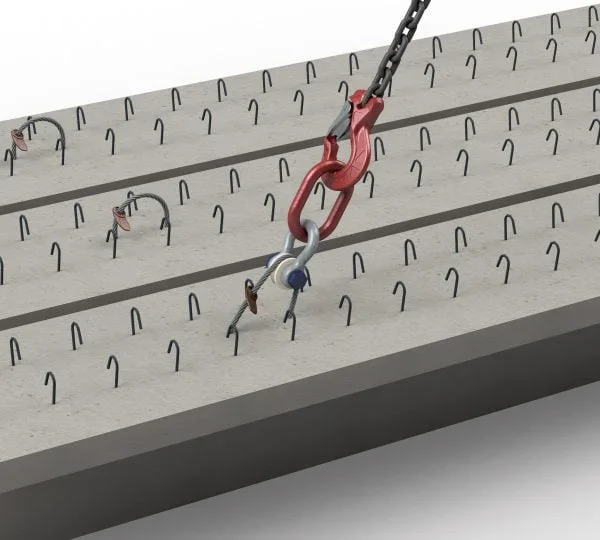

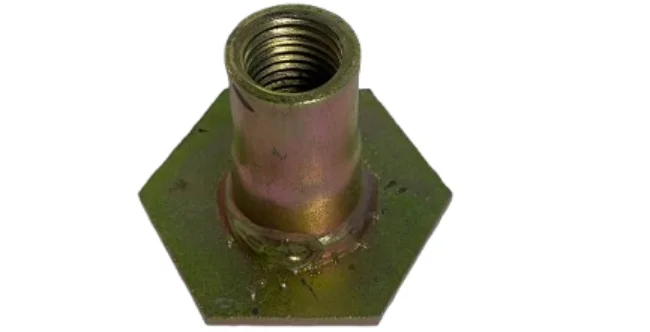

In lifting and material handling, a lifting loop acts as an intermediary between lifting hooks and a load. Lifting loops enable safe and efficient lifting in heavy construction, factory production lines, or the transportation business.

These small but crucial components perform their functions, and their integrity directly impacts safety. A ruptured lifting loop can be the cause of accidents, loss of productive time, and destruction of costly material.

Due to their important function, maintenance is not an option but a necessity. Effective monitoring of wear and maintenance procedures can allow organizations to achieve lifting loops’ reliability and durability, and thus be in a position to ensure a safer and more efficient working environment.

How Do You Properly Inspect Wear and Possible Damage on Lifting Loops?

The best protection against lifting loop failure is regular and frequent inspection. Pre-use inspection will also show up early wear that cannot be seen. But what do you need to look for?

Inspection Checklist for the Different Types of Lifting Loops

Wire Rope Lifting Loops

- Are there broken or frayed strands? Check along the entire length for cut or loose strands that compromise the strength of the loop.

- Any rust or corrosion present? Exposure to moisture can create rust, which diminishes the load-carrying capacity of the rope.

- Are there any crushing, kinks, or deformations?They may be caused by improper handling and create points of stress.

- What about the loop?Run your hand along the rope (wear gloves for hand protection) to detect wire breaks or distortions within.

Forged or Cast Lifting Loops

- Are there any cracks or fractures?Small cracks can open under load, leading to catastrophic failure.

- Is it deformed or bent?An out-of-round loop indicates possible overloading or excessive stress.

- What is the condition of the surface?Signs of excessive wear, gouges, or other damage that may weaken structural integrity should be identified.

Why Document Inspections?

A record of inspections gives a history of the condition of the lifting loop throughout its life, allowing replacement and maintenance on time. The records must include:

- Date of inspection

- Results (e.g., corrosion, damage, wear)

- Work done (repair, replacement, continued in service)

What Are the Most Common Causes of Lifting Loop Damage?

Understanding why lifting loops fail prevents unnecessary wear and tear and extends their life.

Major Factors Responsible for Wear and Tear

1. Overloading the Lifting Loop

- SWL overloading is a primary reason for loop failure.

- Overloaded loops will deform, crack, or fail catastrophically, with severe safety implications.

2. Improper Handling and Use

- Improper uses of lifting loops will exert abnormal stress.

- Twisting, jerking, or dragging the load will exert dangerous forces on the loop.

3. Harsh Environmental Exposure

- Excessive heat, humidity, and corrosive chemicals will accelerate material deterioration.

- Salt exposure at seashore locations can lead to rust and shorten metal loops’ lifespan.

4. Improper Storage Conditions

- Physical damage in the form of bending, kinking, or corrosion from improper storage.

- Loops that are subjected to moisture and dust can lead to premature wear.

5. Failure to Periodically Inspect and Maintain

- Minor wear if not addressed can become catastrophic failures.

- Lack of maintenance is the principal reason for accidents.

How to Prevent Damage to Lifting Loops?

Prevention is always better than repair. Proactive steps can go a long way in enhancing the life and reliability of lifting loops.

Best Practices in Lifting Loop Maintenance

1. Observe Safe Working Load (SWL) Limits

- Inspect the SWL marking on the loop every time before use.

- Train operators to estimate load weight before lifting.

2. Use Lifting Loops Correctly

- Use loops solely for the purpose they are intended for.

- Prevent jerking, twisting, or dragging of the load suddenly.

3. Proper Operator Training

- Instruct operators in correct use, inspection, and maintenance of lifting loops.

- Encourage following safe lifting procedures.

4. Proper Storage of Lifting Loops

- Store loops in a dry, clean, well-ventilated area.

- Utilize storage racks as suggested to prevent kinking or deforming.

5. Implement a Regular Inspection Schedule

- Conduct daily pre-use inspections and more thorough periodic inspections.

- Increase frequency of inspection with severity of use and environment.

6. Keep Lifting Loops Clean

- Remove dirt, grease, and other materials which conceal damage.

- Use non-corrosive cleaning methods for durability.

7. Select Materials by Environment

- Use stainless steel or coated lifting loops in corrosive environments.

How Often Should You Conduct Formal Inspections?

Factors Which Affect Inspection Intervals

- Frequency & severity of use– More frequent heavy use requires more frequent inspection.

- Environmental conditions – More extreme environments require closer examination.

- Manufacturer guidelines – Follow strictly authorized recommendations.

- Regulatory standards – Perform in accordance with industry safety standards.

Suggested Inspection Cycles

| Type of Inspection | Frequency |

| Daily visual checks | Before each use |

| Weekly inspections | Light-duty applications |

| Monthly inspections | Moderate use or outdoor exposure |

| Quarterly inspections | Heavy-duty or high-risk environments |

What Do You Need to Do if a Lifting Loop is Damaged?

When damage is found, prompt action must be taken to prevent failures.

Procedures When Damage is Found

1.Take Out of Service–Stop usage immediately.

2.Tag It–Label clearly with “Out of Service” to prevent improper use.

3.Evaluate the Damage–Determine if repair or replacement is needed.

4.Follow Manufacturer Instructions–If repairable, only allow authorized individuals to do so.

5.Document the Incident–Maintain records for ready reference and compliance for safety.

How Do Safe Lifting Techniques Enhance the Longevity of Lifting Loops?

Apart from maintenance, safe lifting techniques are also required to help extend the life of lifting loops.

Most Crucial Lifting Best Practices

- Plan each lift– Load weight, route, and possible hazards are to be measured.

- Correct lifting methods– Never twist, jerk, or employ sudden movement.

- Load weight– Refrain from placing uneven stress on the loop.

- Use mechanical aid where necessary– Do not impose unnecessary strain on loops and handlers.

- Communicate effectively– Ensure easy coordination of crews.

Why BaoQi for Your Lifting Loop Need?

Where safety and reliability cannot be compromised, quality lifting equipment is essential. BaoQi Tech, an over a decade experienced company, is a high-quality forging, casting, and punching parts expert.

Why BaoQi?

- ISO-9001 Certified Factories–High-standard production guaranteed.

- Durable & Reliable Materials–High load-bearing capacity.

- Industries Globally Trust Them–Proven history in lifting solutions.

Get in touch with BaoQi Tech today for durable and robust lifting loops:

Conclusion: Prioritize Maintenance for Safety & Efficiency

Lifting loops are essential to safe goods handling. By proactive inspection, periodical examination, and proper use, businesses can reduce risks, prevent failure, and attain efficiency. Planned maintenance is investing in safety and productivity.