The construction of reliable, durable, and safe structures involves choosing the right precast concrete fixing socket. These special components will ensure the secure connection of precast concrete elements and preserve the structural integrity of the whole project. The choice of fixing socket significantly influences safety, efficiency, and cost-effectiveness in construction. This guide will walk you through everything you need to know about precast concrete fixing sockets and how Baoqi Tech can help you choose the best solution for your project.

Why Choosing the Right Precast Concrete Fixing Socket Matters

Using a badly inappropriate type of fixing socket may result in connections being unstable, unsafe, and causing costly delays. A correctly chosen socket ensures your precast components fit properly and safely. The important advantages of choosing the right option include:

- Enhanced Safety:Appropriately chosen sockets keep precast concrete elements securely in place at all times, reducing the risks associated with structural failure during and after construction.

- Improved Efficiency:The right socket simplifies the installation process, saving both time and labor, leading to smoother project execution.

- Cost-Effectiveness:With fewer reinforcements or repairs needed, the right socket choice can lower overall project costs.

- Long-Term Durability:A high-quality socket ensures that your precast elements endure for many years, even in challenging environments.

With over ten years of experience, Baoqi Tech dedicates itself to the provision of durable, quality fixing solutions for your precast concrete projects.

Key Considerations in the Selection of Precast Concrete Fixing Sockets

The selection of a fixing socket will be determined by various factors, including socket design, material strength, ease of installation, and resistance of the environment. The following are some key aspects to consider:

1. Socket Design: Bent End, Crimped End, Cross Bar, and More

Various designs of precast concrete fixing sockets exist which are for different applications.

Bent End Sockets: These are typically used for beams, columns, walls, and municipal projects. Because of the bent end design, extra reinforcement is not required, hence reducing the time of installation and minimizing costs. These sockets have been designed with a safety factor three times the required tension. Made from extra robust 20# steel or stainless steel, they are strong, flexible, and up to the task.

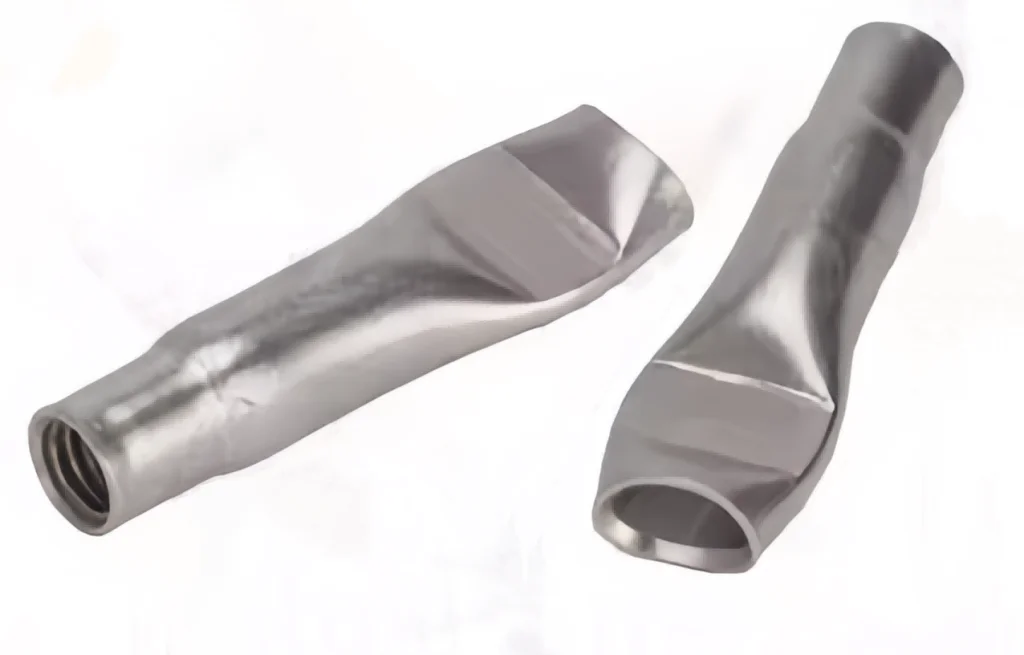

Crimped End Sockets: Ideal for road and bridge construction, supporting beams, columns, and walls. The crimped design ensures direct force transfer to the concrete, increasing stability without additional reinforcement. Constructed from stainless or galvanized steel, they offer resistance to corrosion, making them suitable for harsh environments.

Cross Bar Sockets: These are ideal for assembling structural components, such as building frames and bridges. A cross-bar design allows better load-carrying ability and ease of installation. Many of them are made from galvanized or stainless steel for industrial and commercial purposes where strong connections are necessary.

Precast Accessories Fixing Socket with Cross Pin Nail Plate: Suited for high-rise buildings and infrastructure projects, this design will provide fast, accurate connections with increased shear resistance and stability. Constructed from high-strength steel or stainless steel, it ensures top-notch performance in large-scale construction.

2. Material Strength and Durability

The selection of the right material for your fixing sockets will ensure their long-term performance and resistance to environmental factors. Depending on the location of your project, the following materials can be considered:

Stainless Steel: It is suitable for environments with moisture, salty air, or corrosive conditions.

Galvanized Steel: With good corrosion resistance, it is cheaper and suitable for most construction environments.

20# Steel: Suitable for projects requiring high load-bearing capacity, offering robust strength.

The selection of the right material means that the fixing sockets will last for the duration of the project and beyond.

3. Ease of Installation

Installation efficiency is critical to meeting project timelines. Designs by Baoqi Tech, such as cross-bar and crimped end sockets, are engineered to be installed quickly and easily, reducing setup errors and speeding up construction.

4. Fabrication to Suit Project Requirements

Every construction project is different, and Baoqi Tech offers customizable fixing sockets to meet particular project needs. Whether it’s a high-rise, bridge, or industrial structure, we have solutions designed to match your specifications.

5.Corrosion Resistance and Long Life

In harsh environments, fixing sockets with high corrosion resistance should be selected. Baoqi Tech’s stainless steel and galvanized steel sockets offer excellent resistance to rust and deterioration, ensuring long-lasting performance of your precast concrete elements.

6.Safety and Load-Bearing Capacity

Safety is a priority in construction. Baoqi Tech’s fixing sockets are tested under the most stringent conditions to ensure that they can bear heavy loads and harsh conditions without compromising structural integrity.

Practical Applications of Precast Concrete Fixing Sockets

Baoqi Tech precast concrete fixing sockets are applied in various projects, ranging from high-rise buildings to huge infrastructure projects. Some of the common applications include:

High-Rise Buildings: The Precast Accessories Fixing Socket with Cross Pin Nail Plate is suitable for connecting beams, columns, and slabs in high-rise construction with superior seismic performance and structural stability. ·

Road and Bridge Infrastructure: Baoqi Tech’s fixing sockets provide reliable, secure connections for the components of roadways and bridges, withstanding the heavy demands of these critical structures.·

Municipal Engineering Projects: Our products are used in infrastructure projects such as railways and underground pipe galleries, providing reliable connections for pipelines, cables, and other essential components.

Why Choose Baoqi Tech for Your Precast Concrete Fixing Sockets?

With over 10 years of industry experience, Baoqi Tech is the go-to partner for precast concrete fixing socket solutions. Here’s why:

Comprehensive Product Range: Whether you require a bent end, crimped end, or cross-bar socket, we offer a diverse range of options suited for different applications.

Customized Solutions: We collaborate closely with clients to provide fixing sockets tailored to specific project needs.

Global experience: With a good track record of performance in countries like Australia, Canada, the United States, and Germany, Baoqi Tech has the capability to undertake large-scale projects in any part of the world.

Quality Assurance: All the products from Baoqi Tech are manufactured in ISO-9001 certified plants, rigorously tested, and SGS certified to ensure top-quality performances.

Conclusion: Make the Right Choice with Baoqi Tech

Choosing the right precast concrete fixing socket is crucial to the success of your construction project. At Baoqi Tech, we can help you secure your precast elements for long-term safety, efficiency, and durability. We have a wide selection of high-quality, customizable solutions to support you through every stage of your project.

Ready to take the lead in optimizing your construction projects? Contact Baoqi Tech today to explore our precast concrete fixing sockets and discover how we can support you in reaching your project goals.

Contact Us:

- Phone: +0086 13793240603

- Email: freya@baoqitech.comor sales@jcdgroup.com.cn

- Website: Explore our full range of precast concrete solutions

Let Baoqi Tech be your trusted partner for the safety, durability, and efficiency of your precast concrete components.