Understanding Anchor Plates and Their Applications

Definition and Purpose of Anchor Plates

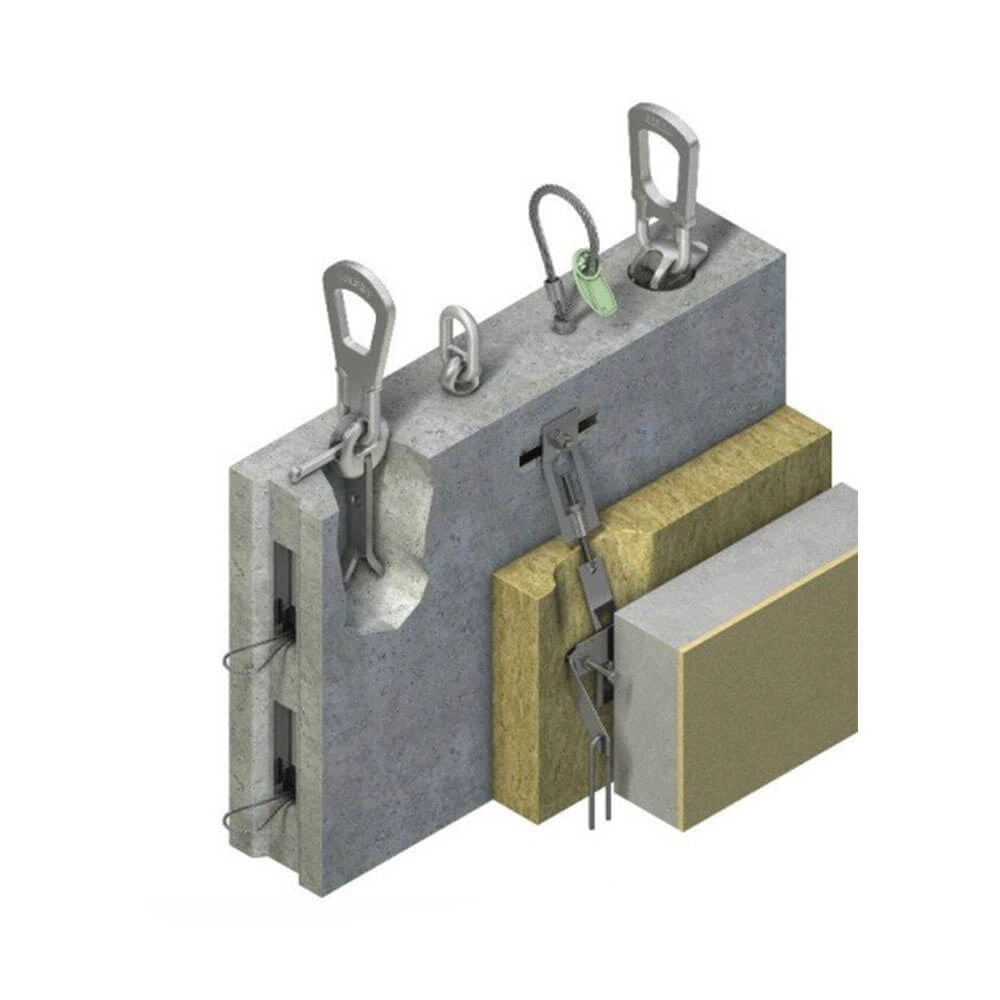

Anchor plates, commonly referred to as wall washers or bearing plates, are flat, typically rectangular or square-shaped metal components used in construction and engineering to distribute load and enhance structural stability. Their main function is to secure and reinforce walls, roofs, bridges, and various other structures, ensuring long-lasting durability and preventing structural failures. By using anchor plates, the pressure applied to the structure is evenly distributed, thereby increasing its strength and resilience.

Common Uses in Construction and Engineering

In construction and engineering, anchor plates are commonly deployed in a variety of settings. They are frequently used in masonry and timber-framed buildings to hold tension rods or anchor bolts in place. In bridge construction, anchor plates ensure that the tension and compression forces are adequately managed, which is pivotal for the stability of the structure. These plates are also utilized in reinforcing retaining walls, historical building renovations, and even in modern skyscraper constructions for added structural integrity.

Materials Used in Manufacture

The materials chosen for manufacturing anchor plates significantly influence their performance and longevity. Typically, these plates are made from high-strength materials such as steel, cast iron, or stainless steel. Steel is preferred due to its excellent load-bearing capacity and resistance to environmental factors. For applications exposed to aggressive environmental conditions, galvanized steel or stainless steel is used to prevent corrosion and improve durability. The choice of material depends on the specific requirements of the project and the environmental conditions where the anchor plates are deployed.

Factors Influencing the Size of Anchor Plates

Load-Bearing Capacity Requirements

The size of anchor plates is directly related to the load-bearing capacity required for a particular application. The plate must be large enough to distribute the forces exerted on it over a substantial area, minimizing the risk of localized wall failures. Engineers often calculate the expected load and choose a plate size that can safely handle the anticipated stresses. This calculation ensures that the structural integrity is maintained without unnecessary material usage.

Type of Structure and Environmental Conditions

The type of structure where anchor plates are utilized also determines the required size. For example, larger and more intricate constructions like bridges and skyscrapers necessitate bigger anchor plates to maintain stability. Environmental factors, including exposure to wind, water, and seismic activity, also affect the plate’s dimensions. In regions with harsh weather conditions, larger anchor plates may be essential to endure additional forces and avert structural failures.

Compatibility with Other Structural Components

Another critical factor in determining the size of anchor plates is their compatibility with other structural components. The plate must be appropriately sized to fit the bolts, rods, or other anchoring mechanisms used in construction. This compatibility ensures that the anchoring system functions as intended, providing the necessary support and stability. Misalignment or incorrect sizing can lead to ineffective load distribution and potential structural issues over time.

Methods to Determine Suitable Sizes for Anchor Plates

Engineering Calculations and Principles

Stress Distribution Analysis

A thorough analysis of stress distribution is a primary method to determine the appropriate size of anchor plates. This involves calculating the forces acting on the plate and the surrounding structure, ensuring that the plate can handle these forces without failing. Engineers assess the stress concentrations and decide on a size that ensures even distribution, which is critical in preventing structural damage.

Safety Factor Considerations

Safety factors are integral to the design of anchor plates. These factors provide a margin of error to account for unexpected loads and material imperfections. By applying safety factors, engineers can determine a suitable size that not only meets the theoretical requirements but also ensures additional security. This practice helps in maintaining the integrity of the structure even under unforeseen conditions.

Industry Standards and Guidelines

Building Codes and Regulations

Building codes and regulations are essential in defining the dimensions of anchor plates. These codes offer standardized guidelines that must be adhered to, guaranteeing the safety and reliability of structures. Adhering to local and international regulations ensures that the plates are correctly sized and comply with all required safety standards. This compliance is crucial for obtaining approval and ensuring the durability of construction projects.

Expert Recommendations

Expert recommendations, often based on years of experience and specific project insights, are invaluable in sizing anchor plates. Engineers and architects rely on these recommendations to make informed decisions about plate sizes. These expert insights often complement standard calculations, providing practical guidance that enhances the overall effectiveness and safety of the anchoring system.

Case Examples of Different Anchor Plate Sizes in Various Projects

Residential Building Applications

In residential building applications, anchor plates are commonly used in small to medium-sized houses and apartments. For such structures, the plates are typically smaller, but their size must still be sufficient to handle the loads of walls and roof systems. They are essential in ensuring that connections between structural components, such as beams and walls, are secure and capable of bearing the loads they encounter daily.

Commercial Building Utilizations

Commercial buildings, such as office buildings and retail spaces, often require larger anchor plates due to the more significant loads and larger spans involved. The plates used in these applications are designed to support higher weight loads, ensuring the stability of expansive areas and multi-story structures. Properly sized anchor plates in commercial buildings are crucial for maintaining safety and functionality, especially in high-traffic environments.

Industrial Projects Insights

In industrial projects, including factories and large-scale facilities, there is often a need for anchor plates of considerable size and strength. These structures generally endure heavy machinery loads, vibrations, and dynamic forces. Therefore, the anchor plates used must be sufficiently robust to manage these factors without compromising the stability of the structure. The selection of size and material becomes even more critical in such demanding environments to guarantee long-term operational safety and efficiency.

Tips for Selecting the Right Size for Specific Projects

Consulting with a Structural Engineer

Consulting with a structural engineer is indispensable when determining the ideal size of anchor plates for any project. Structural engineers possess the technical expertise to analyze the load requirements and environmental conditions specific to each project. They use sophisticated calculations and design principles to recommend the correct size of anchor plates that will ensure the long-term stability and safety of the structure. Additionally, their insights can help identify potential risks associated with incorrect sizing and provide solutions to mitigate these issues.

Conduct Site Assessments

Conducting comprehensive site assessments is crucial for selecting the right size of anchor plates. These assessments involve evaluating the structural demands of the site, including the type of soil, existing load conditions, and the impact of environmental factors such as wind and seismic activity. By understanding these site-specific variables, engineers can make informed decisions about the appropriate size and material of anchor plates required. A detailed site assessment ensures that the selected anchor plates will perform adequately under the given conditions, contributing to the overall resilience of the structure.

Using Simulation Software

Utilizing simulation software can significantly enhance the process of selecting the right size for anchor plates. Modern engineering software allows for the modeling and simulation of various load scenarios and structural behaviors. By inputting specific parameters related to the project, engineers can visualize how different sizes of anchor plates will perform under various conditions. This technology aids in optimizing the design by predicting potential issues and ensuring that the selected anchor plates provide the necessary support. Simulation software serves as a powerful tool in achieving precision and confidence in the sizing process.

Potential Consequences of Incorrectly Sized Anchor Plates

Impact on Structural Integrity

The stability and strength of a building or infrastructure are greatly influenced by the correct sizing of anchor plates. Undersized plates can lead to uneven load distribution, causing stress concentrations that may result in cracking or, in extreme cases, structural failure. On the other hand, oversized plates can lead to unnecessary material expenses and installation difficulties. Hence, improper sizing can weaken the entire structure’s strength and durability, posing substantial risks to its long-term integrity.

Increased Maintenance Costs

Incorrectly sized anchor plates can also lead to increased maintenance costs. Improper load distribution can cause accelerated wear and tear, leading to more frequent repairs and replacements. This not only disrupts the functionality of the structure but also incurs additional expenses. Furthermore, addressing the issues caused by incorrectly sized plates might require more extensive interventions, such as structural reinforcements or even partial demolitions, further driving up maintenance costs.

Safety Hazards

Safety hazards are a critical concern when it comes to the incorrect sizing of anchor plates. Insufficient plate size can result in structural instability, posing a danger to occupants and users. In extreme cases, this can lead to catastrophic failures, endangering lives and causing substantial property damage. Properly sized anchor plates are essential for ensuring the safety of a structure, protecting both the investment and its users.

Final Thoughts on Choosing the Perfect Size for Anchor Plates

Choosing the appropriate size for anchor plates is a multifaceted process that requires detailed analysis and informed decision-making. By consulting with structural engineers, conducting thorough site assessments, and utilizing advanced simulation software, you can make well-founded choices that contribute to the structural integrity and longevity of your projects. The consequences of incorrectly sized anchor plates underscore the importance of precision in this aspect of construction and engineering.

Ensuring that anchor plates are sized correctly not only improves the durability and safety of a structure but also reduces long-term maintenance expenses and lessens potential safety risks. Following industry standards and utilizing expert advice further enhances the dependability of your anchoring systems. In conclusion, the careful selection of anchor plates is crucial in attaining resilient, safe, and cost-effective construction results.

Anchor plates are an essential component in the construction industry, and BAOQI is a leading manufacturer and supplier of high-quality anchor plates.

BAOQI‘s anchor plates are designed to provide a secure and reliable connection between structural elements, such as beams, columns, and walls. They are made from durable materials, such as steel or stainless steel, ensuring long-lasting performance and resistance to corrosion.

One of the key features of BAOQI‘s anchor plates is their versatility. They come in various sizes and designs to accommodate different construction requirements. Whether it’s a small residential project or a large-scale commercial building, BAOQI has anchor plates that can meet the specific needs of any construction project.

In addition to their durability and versatility, BAOQI‘s anchor plates are also known for their ease of installation. They are designed to be easily integrated into the construction process, saving time and effort for builders and contractors.

Furthermore, BAOQI is committed to providing excellent customer service. They have a team of knowledgeable professionals who can assist customers in selecting the right anchor plates for their projects and provide technical support when needed.

Overall, BAOQI’s anchor plates are a reliable and efficient solution for ensuring the stability and strength of construction structures. With their high-quality materials, versatility, and excellent customer service, BAOQI is a trusted choice for anchor plates in the construction industry.