Construction equals mega projects, skyscrapers, and high safety standards. Among many risky operations, lifting heavy loads is a highly responsible operation that demands utmost care. Right in the middle of these operations is a self-explanatory but no less significant piece of equipment: the lifting loop.

But are we really making our best efforts to attain the highest levels of safety in their utilization? This article provides the main principles, integration processes, maintenance needs, and industry practices that can aid in making every lift a safe one.

What are the Basic Principles that Ensure Safe Use of Lifting Loops?

There is a requirement to build a sound foundation in the shape of fundamental safety guidelines prior to one adopting lifting loops. The guidelines help lifting loops function as needed and lower the danger of accidents.

Are Lifting Loops Made of Quality Materials?

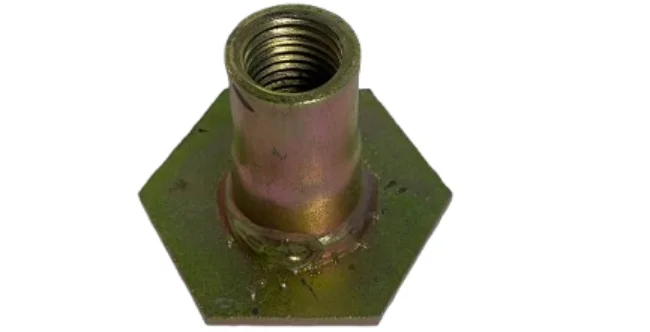

One of the core safety aspects is the material quality used in making lifting loops. Are lifting loops constructed using high-strength steel wire that does not fail or deform under expected loads?

Material quality translates into durability, strength, and minimal chances of failure when subjected to pressure.

How Important Is Load-Bearing Capacity?

Every lifting loop will have an allocated load-carrying capacity, to be strictly observed. Overloading of a lifting loop is maybe one of the most common yet dangerous mistakes in lifting operations that might result in equipment failure and serious accidents.

Why Is Compatibility With Other Lifting Equipment Important?

Lifting loops are not independent products—they must be compatible with lifting hooks, slings, and other lifting equipment. Securing the connection reduces the chances of it detaching or losing stability when lifted.

What Is the Role of Pre-Use Inspections in Safety?

They should be checked in detail and time and again before being used for the first and last time. Damage, wear, and corrosion inspection puts the lifting loop into an ideal condition to work.

Neglecting tiny failures will undermine the structural strength of the loop and result in disastrous failure.

How Should Lifting Loops Be Incorporated Into Safe Lifting Practices?

Even the ideal lifting loop is useless when mistreated. Incorporation into lift procedures is most crucial in ensuring safe and effective operation.

How Do We Know that Attachment is Secure?

A lifting loop should be attached safely on the load and the lifting gear for stability to be assured. Before undertaking a lift, it is greatly important that the load be balanced and securely attached.

How Do Angles of Lift Affect Safety?

Different lifting angles place different amounts of stress on the lifting loop. Wire rope lifting loops, for instance, will endure both axial and angle lifting, but their limitations under a range of angles need to be known. Overlateral stress can erode the loop and cause unplanned failure.

How Do We Prevent Maximum Damage in Lift?

Avoiding direct contact with rough edges is required because rough surfaces have the potential to compromise the loop and its strength. In addition, smooth and controlled lift motions avoid over-stressing the loop.

What Maintenance and Inspection Procedures Maximize Lifting Loop Life?

Safety is not a single task but an ongoing process. Maintenance and inspections play a key role in preserving the integrity of lifting loops.

How Often Should Inspections Be Performed?

The frequency of inspection should be balanced against the degree of stress and service environment. In cases where stress is acute, daily inspection may be necessary, but reduced frequency may be adequate for lower stress service.

What are the Signs a Lifting Loop Needs to Be Replaced?

Lifting loops need to be removed from service promptly if they indicate any of the following signs:

●Fraying or kinking

●Corrosion or rusting

●Deformation or structural damage Failure to recognize these warning signs increases the failure probability, which leads to potential injuries and costly delays.

Why is Keeping Inspection Records Important?

Documentation of maintenance and inspection leaves some record of the state of the loop. In addition to improved safety monitoring, this adds to industry compliance.

What Role Do International Standards Play in Elevating Loop Safety?

Safety in construction is made possible through adherence to international safety standards and certification in an attempt to attain loops for lifting that are of high quality and standards.

Why Should Certifications like ISO 9001 Be Relevant?

ISO 9001 type of certifications guarantees adherence to quality management systems of high quality standards. Businesses with such certifications have routine manufacturing processes with established procedures to guarantee consistency of quality and reliability in lifting equipment.

Are There Particular Standards That Control Lifting Equipment?

Although there are no standards for lifting loops, firm-wide codes such as EN 13414 for wire rope slings act as a benchmark for safety. In selecting lifting loops, conformity to these standards is evidence of best practice.

How Can Construction Teams Develop a Safety Culture for Lifting Operations?

Safety on lifting operations is more than equipment—it requires a good safety culture from all individuals.

Why is Training Critical to Lifting Safety?

Full training programs guarantee the workers are aware of proper use, inspection, and safe use restrictions of lifting loops. Proper training keeps human error under control and guarantees safety.

How Can Communication Improve Safety?

Good lines of communication ensure workers are not hesitant to report danger without fear of punishment. Open safety discussions make risk assessment a priority.

Why Are Risk Assessments Important as Standard Practice?

Performing risk assessments before every lift helps identify potential dangers. By evaluating factors such as weight distribution, lifting angles, and environmental conditions, teams can implement appropriate safety measures.

How Does BaoQi Support Safe Lifting Practices?

Choosing the right supplier for lifting equipment is crucial in maintaining safety and efficiency. BaoQi Tech is a trusted provider of high-quality forging and casting parts, including robust lifting loops.

What Sets BaoQi’s Lifting Loops Apart?

BaoQi lifting loops are made with durability, high strength, and strict quality control in mind. They work hard to produce their products to meet international safety standards.

How Does BaoQi Ensure Product Reliability?

With ISO 9001-certified facilities and more than a decade of experience, BaoQi places emphasis on safety and performance.

Their engineers offer professional advice on product selection to ensure that customers receive the most appropriate lifting solutions for their intended use.

Is It a Good Idea to Invest in High-Quality Lifting Loops?

Yes. The monetary cost of lifting accidents, from injury to project delay, is several times higher than the investment cost of high-quality, certified lifting loops.

Focusing on safety and working with reliable suppliers like BaoQi can assist construction companies in creating a safer, more efficient working environment.