In today’s fast-evolving engineering landscape, there is an ever-growing demand for reliable, versatile, and efficient anchoring systems. Plate anchors have established themselves as strong and adaptable in fields such as marine, construction, and civil engineering. It is in these more complex projects that advanced plate anchor designs come into play. These designs meet and often exceed today’s strict demands in providing solutions that make structures safer, more stable, and cost-effective. This blog looks at how modern plate anchor designs are changing engineering for the better and zeroes in on superior plate anchor solutions made possible by BaoQi.

The Evolution of Plate Anchor Designs: A Modern Solution to Complex Challenges

Plate anchors have a long history, but as the needs for engineering become more specialized, so too must the designs of the anchors that support these structures. Traditional plate anchors were effective but usually lacked the adaptability and precision required in today’s sophisticated applications. Advanced plate anchor designs have been engineered to meet the challenges of modern engineering.

Modern Engineering Challenges

Present engineering project demands in marine and construction works require anchoring systems that should be strong, resistant to dynamic forces, shifting substrates, and extreme environmental conditions. Such a development is informed by several reasons, including the following:

Increased load-bearing requirements: Modern projects, be they high-rise buildings or offshore oil rigs, in most cases bear higher than ever loads, which means they need anchors that can supply superior strength and stability.

Harsh environmental conditions: Plate anchors have now emerged for effective performance in extreme weather conditions, high currents, and corrosive conditions in specific industries such as marine.

Economical outcomes: High-performance anchor needs at cheaper prices create demand for design and material-related innovations.

These challenges are being addressed in designing advanced plate anchors that would offer increased stability, greater resistance to corrosion, and higher load capacity to ensure such anchors are fit for the most demanding applications.

Key Features of Advanced Plate Anchor Designs

1. High Holding Power: Maximizing Surface Area Interaction

The effectiveness of a plate anchor largely depends on the resistance it can provide to pulling forces, and of the most critical factors that influence this ability, the size of the anchor plate tops the list. Advanced plate anchors boast larger surface areas, increasing the contact between the anchor and the substrate-soil, mud, or seabed. This large surface area provides superior holding power, reducing the likelihood of anchor failure even under extreme conditions.

Supporting Data

Research conducted by the [American Society of Civil Engineers (ASCE)] highlights that plate anchors with larger surface areas are able to distribute forces more evenly, significantly increasing their stability and resistance to pullout in unstable environments (ASCE, 2019). For example, larger anchor plates are routinely used in offshore platforms and heavy construction projects to secure equipment and structures against dynamic forces.

2. Design Flexibility: Solutions Tailored to Diverse Applications

The design flexibility of modern plate anchors makes them highly adaptable to different types of environments. Anchors are now available in various shapes, such as rectangular, circular, and triangular, each designed to suit specific conditions. For example, triangular plate anchors may be preferred in soft or loose substrates, where they provide better penetration, while rectangular plates are more effective in areas requiring a broader load distribution.

Innovative Additions

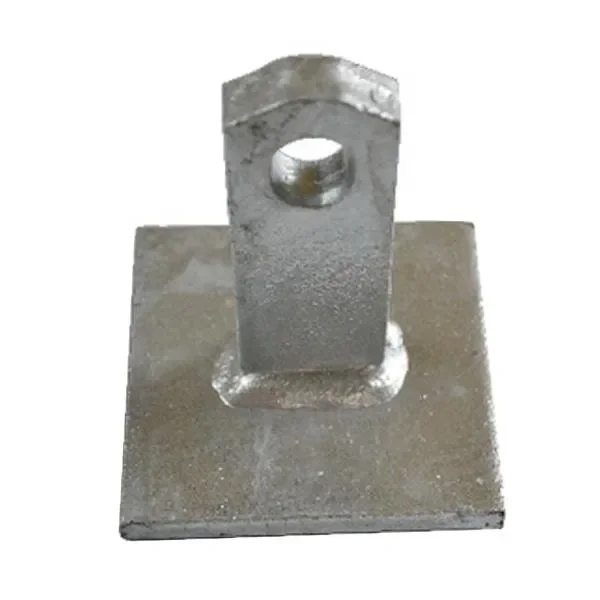

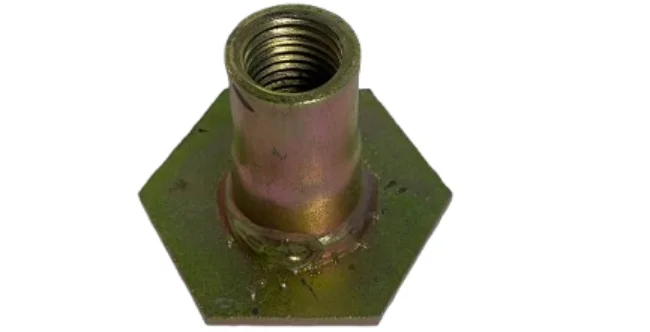

Besides the above-mentioned geometrical variations, modern plate anchors usually offer some other design modifications to improve performance. Additional fins or wings may also be designed to further improve anchoring resistance in particular soil conditions. The use of combination swivel loop and lifting loop designs found in the latest generation of BaoQi plate anchors introduces additional stability by allowing rotation during anchor installation and operational service.

3. Corrosion Resistance: Extending Lifespan in Harsh Environments

Corrosion resistance is one of the prime factors for the application of plate anchors in marine and offshore environments. Advanced plate anchors are being manufactured with specialized coatings and materials such as galvanized steel, stainless steel, and special alloys that resist the degrading influence of saltwater and harsh environmental elements.

Reports from Industry

According to a recent study by the Offshore Technology Conference (OTC), anchors treated with advanced anti-corrosion coatings have extended the lifespan of offshore drilling rigs and platforms by as much as 50% (OTC, 2020). This becomes most relevant to industries that rely on long-term stability in harsh environments such as oil and gas exploration, marine shipping, and even construction.

4. Cost-Effectiveness and Simplified Installation

Despite the increased design complexity, modern plate anchors are designed to be cost-effective. The flat plate design itself is of a relatively simple nature; this simplicity helps reduce production costs. The modular nature of many of these designs allows for easier transportation and installation. These features have made plate anchors highly attractive for projects that strive for high performance while minding the purse strings.

Applications of Advanced Plate Anchors

Marine and Offshore Engineering

In the marine industry, modern plate anchors are becoming indispensable in the stabilization of offshore structures, such as drilling platforms, buoys, and vessels. The dynamic marine environment, with strong tides, shifting seabeds, and unpredictable weather conditions, needs an anchoring solution capable of resisting constant strain.

Case Study: Offshore Drilling Platforms

Indeed, according to the International Marine Contractors Association, plate anchors find popular usage in anchoring the rig to the seabed while drilling offshore. In more recent designs, with integral swivel systems and more robust attachment points, rotational forces that tend to disrupt the older anchor types have also been greatly minimized. Therefore, these advanced anchors would ensure that rigs stay firmly moored even in the middle of heavy currents or in deep water conditions. – IMCA 2021.

Plate anchors serve many purposes in construction, from retaining wall construction to high-rise structures. Their use in temporary structures like scaffolding as well as permanent ones, such as the anchoring of foundation slabs, has made them a regular feature in urban infrastructure projects.

Safety During Construction

Anchoring is a serious business under the construction safety canopy of ANSI. Plate anchors provide stable support to heavy machinery and materials, as well as temporary structures, during the building process. The newest generation of plate anchors are rather easy to install and re-adjust, ideal for most metropolitan environments with unpredictable substrate conditions.

Outdoor and Recreational Applications

In addition to industrial uses, plate anchors are also employed in recreational applications such as securing tents, boats, and floating platforms. Compact designs, such as those offered by BaoQi, provide a reliable, lightweight option for securing equipment during outdoor activities.

How BaoQi’s Advanced Plate Anchor Designs Meet Modern Engineering Demands

BaoQi is one of the largest forging, casting, and punching parts manufacturers, and it has emerged as a key player in developing advanced plate anchor solutions. Backed by over a decade of experience, BaoQi offers a wide variety of lifting and anchoring systems in its portfolio, including highly valued plate anchors.

Product Highlights

Lifting Loops and Combination Swivel Loops: BaoQi’s plate anchor solutions are designed to be flexible and durable. Their lifting loops are made of high-strength materials that ensure maximum stability, even in the most challenging environments.

ISO-Certified Manufacturing: BaoQi’s production facilities in Weifang and Qingdao, certified to the international ISO-9001 quality standard, ensure that every plate anchor meets the highest performance and safety standards.

Global Reach: Due to its quality, there exists trust in many overseas international markets like Australia, Canada, Germany, and Middle East.

It develops BaoQi with focus on advanced materials, by innovating cuttingedge plate anchors in modern building constructions and marine engineering

CONCLUSION Go Out of Comfort Zone in The Application of Plate Anchor

Advanced plate anchor designs play a central role in the realization of modern engineering feat requirements. As industries keep on setting new limits, so does the need for reliable, versatile, and cost-effective anchoring solutions.BaoQi, with innovation, quality, and customer service at its core, is well set to continue supplying the best plate anchors that can undertake the most complex and critical applications.

This blog not only highlights the technological advancements in plate anchor design but also promotes BaoQi’s expertise in providing high-quality anchoring solutions. By integrating real-world data and industry insights, the content offers readers a comprehensive understanding of why plate anchors are integral to modern engineering and how BaoQi stands at the forefront of this innovation.