Understanding Different Types of Anchors

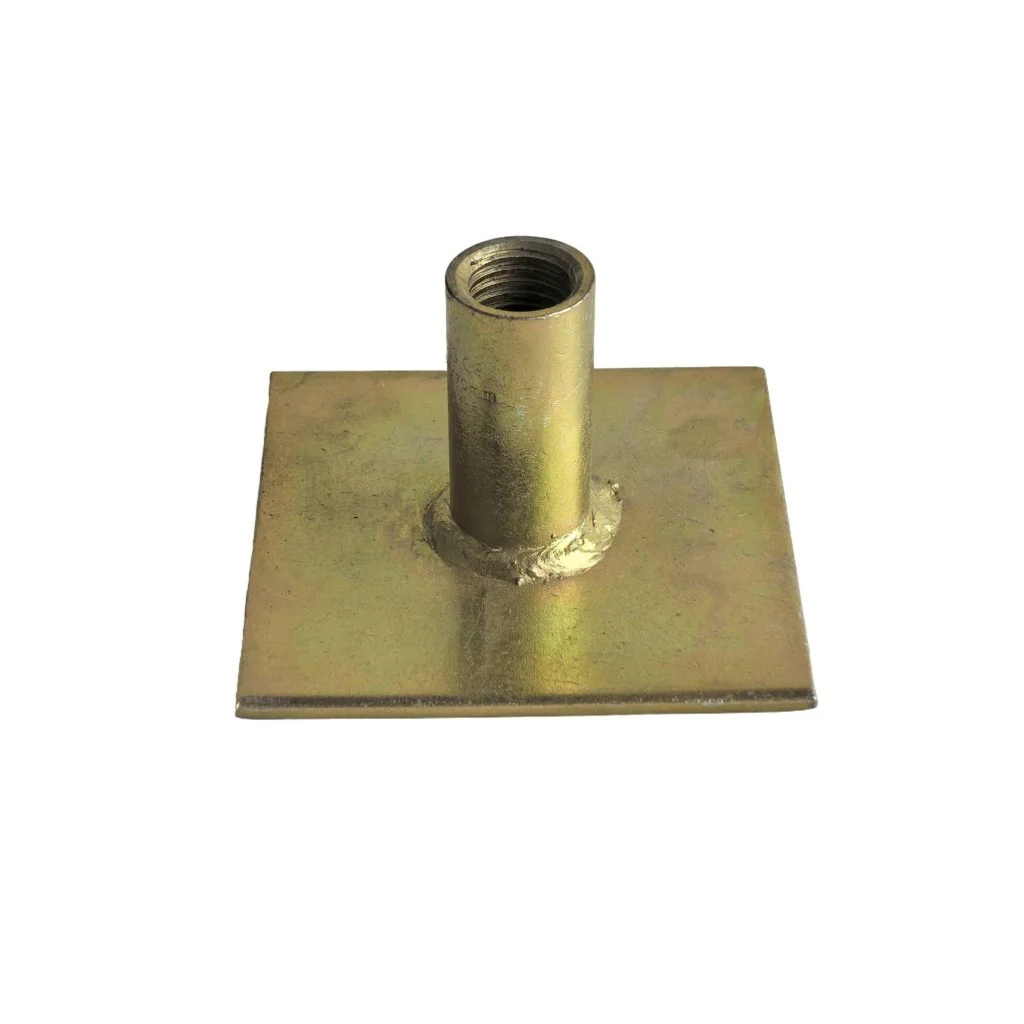

Precast Concrete Barrel Lifting Socket

The Precast Concrete Barrel Lifting Socket serves as a unique anchor widely employed in building projects. It is crafted to support the secure and effective hoisting of hefty precast concrete parts. These sockets take on a cylindrical form and include an internal threaded section, enabling a firm link to lifting equipment. Their sturdy build guarantees they can endure the tremendous pressures experienced during hoisting tasks.

A key benefit of the Precast Concrete Barrel Lifting Socket lies in its adaptability. Just like the products that Baoqi company research, it can be set into concrete pieces like beams, panels, or columns while they are being molded. This embedding ensures the socket becomes a lasting element of the structure, offering dependable assistance throughout its existence. Moreover, these sockets come in different dimensions and weight capacities, rendering them appropriate for diverse uses.

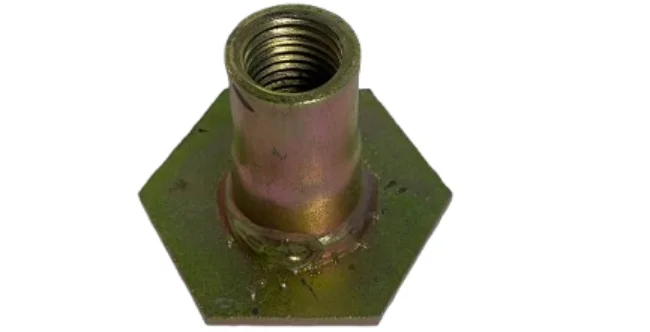

Precast Concrete Flat Anchor

The Precast Concrete Flat Anchor is another vital tool in construction. Unlike the cylindrical Precast Concrete Barrel Lifting Socket, this anchor boasts a sleeker shape. It can be placed flush with the surface of precast components. This trait proves especially handy in situations needing little to no sticking out.

Flat anchors often provide structural backing. They create a solid attachment point for linking other parts or strengthening elements within a framework. Made from tough materials, these anchors ensure lasting performance and resistance to deterioration over time. Their layout also simplifies setup, cutting down on labor expenses and boosting project efficiency.

Other Commonly Used Anchors in Construction

Beyond the Precast Concrete Barrel Lifting Socket and Precast Concrete Flat Anchor, several anchor varieties find frequent use in building endeavors. These include wedge anchors, sleeve anchors, and chemical anchors. Each kind fulfills a distinct role and is picked based on aspects like weight needs, surrounding conditions, and material suitability.

Wedge anchors excel at fastening substantial loads to concrete or brick surfaces. Sleeve anchors provide flexibility and work with various base substances, such as stone or masonry. Chemical anchors use bonding agents to attach to materials, delivering outstanding strength in tough scenarios.

Factors to Consider When Selecting an Anchor

Load Capacity and Strength Requirements

When picking an anchor for a construction task, evaluating its load capacity and strength demands is essential. The anchor must manage the planned weight without risking safety or structural soundness. Engineers usually determine capacities by considering material traits, setup conditions, and expected forces.

For example, a Precast Concrete Barrel Lifting Socket needs to cope with the shifting loads tied to raising heavy items. Likewise, Precast Concrete Flat Anchors used for support must possess adequate pulling strength to resist forces over time.

Material Compatibility and Durability

Material compatibility ranks as a crucial element in anchor selection. The anchor’s makeup should align with or enhance the traits of the nearby material to avoid problems like rust or weakened function. Stainless steel anchors, for instance, are frequently selected for their ability to resist corrosion in severe settings.

Durability holds equal weight since anchors face numerous stresses during their use. Top-grade materials like carbon steel or alloy steel improve an anchor’s lifespan and dependability in challenging situations.

Environmental Conditions and Corrosion Resistance

Surrounding conditions greatly influence an anchor’s appropriateness for a specific job. Elements like temperature changes, moisture amounts, and chemical exposure can affect performance over time.

Anchors meant for outdoor or seaside settings must show superior corrosion resistance to handle water and salty air. Protective layers, such as zinc coating or hot-dip galvanizing, are often added to boost resistance further.

Applications of Precast Concrete Anchors

Barrel Lifting Sockets in Heavy Lifting Projects

Precast Concrete Barrel Lifting Sockets prove essential in projects requiring the movement of large parts into place safely. These sockets offer reliable connection points for cranes or hoists during transport and setup stages.

By placing these sockets into precast pieces during production, builders can enhance workflows while meeting safety rules. Their capacity to manage heavy weights makes them perfect for tasks like bridge building or assembling tall structures.

Flat Anchors in Structural Support Systems

Precast Concrete Flat Anchors play a critical role in support systems by offering steady linking spots between various parts of a structure. Their flush design ensures little disruption to other components while keeping strong attachment abilities.

These anchors often appear in uses like wall panel setups or reinforcement frameworks where stability matters most. Their straightforward installation also helps shorten project durations without sacrificing quality.

Installation Techniques for Precast Concrete Anchors

Proper Handling and Placement Guidelines

Installing precast concrete anchors like the Precast Concrete Barrel Lifting Socket and Precast Concrete Flat Anchor demands careful attention to handling and positioning. Proper handling starts with storing anchors in a clean, dry spot to avoid dirt or rust before use. During transport, they should be packed securely to prevent harm or bending.

Placement stands as a vital step in installation. For a Precast Concrete Barrel Lifting Socket, the anchor must be set into the concrete piece during molding. This ensures a lasting, firm bond capable of handling heavy loads. The socket’s direction should match the planned force path to maximize its effectiveness. Likewise, when setting a Precast Concrete Flat Anchor, it must rest flush with the precast element’s surface. This reduces sticking out and keeps a neat look while offering strong backing.

Accuracy matters greatly during placement. Engineers often rely on templates or guides to position anchors correctly in the mold. Any shift from the intended spot could weaken the anchor’s ability to bear weight or harm the structure’s overall strength.

Ensuring Secure Connections

To guarantee firm connections, following maker guidelines on embedment depth and anchor spacing is key. These details help spread loads evenly across the structure and avoid focused stress points.

For instance, when employing Precast Concrete Barrel Lifting Sockets in heavy lifting, workers must check that the threaded section is clear of debris before attaching lifting gear. This step prevents slipping or breakdowns during use. Regular checks on bolt tightness also maintain secure links over time.

When Precast Concrete Flat Anchors reinforce structures, proper bonding with nearby materials is crucial. Bonding agents or grouting may be used to strengthen anchorage and ensure stability under changing loads.

Safety and Compliance Standards for Anchor Usage

Industry Standards for Anchor Performance

Precast concrete anchors fall under strict industry rules that dictate their performance and safety levels. These guidelines ensure anchors meet set standards for weight capacity, longevity, and environmental resistance.

For example, global standards like ISO 9001 focus on quality control in production. Anchors must pass tough tests to prove they can handle expected forces without failing. These tests might cover pulling strength, wear resistance, and rust protection.

Following these rules is vital in construction where safety cannot be compromised. Builders should always source anchors from trusted makers who follow certified processes.

Regular Inspection and Maintenance Practices

Consistent checks and upkeep are essential to keep precast concrete anchors performing well over their lifespan. Inspections should happen at planned times to spot wear, rust, or damage that could weaken anchor strength.

During checks, engineers look at surface state, alignment precision, and fastener tightness. Any issues found should be fixed quickly with repairs or replacements.

Upkeep tasks might include clearing debris from threaded sections in Precast Concrete Barrel Lifting Sockets or recoating Precast Concrete Flat Anchors in harsh settings. These steps extend anchor life while keeping safety standards intact.

Frequently Asked Questions

What are common uses for a Precast Concrete Barrel Lifting Socket?

It is often used in heavy-lifting tasks like bridge building or high-rise assembly due to its strong load capacity.

How do you ensure correct placement of a Precast Concrete Flat Anchor?

Placement requires embedding it flush with the surface during molding while aligning it with structural needs for best results.

Why are regular checks important for precast concrete anchors?

They help catch wear or damage early, ensuring ongoing safety and rule compliance over time.

Are there specific rules for anchor production?

Yes, standards like ISO 9001 guide quality control in making anchors.

For custom solutions tailored to your building needs, BaoQi company brings over 10 years of skill in crafting high-quality forging and casting parts!