Understanding Concrete Lifting Anchors

Definition and Purpose of Concrete Lifting Anchors

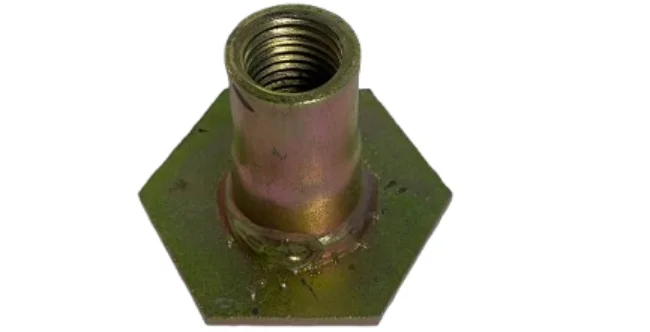

Concrete lifting anchors are vital tools in the building sector. Just like the lifting anchor made by Baoqi company, they aid in safely and effectively managing precast concrete parts. These devices are inserted into concrete elements. This allows them to be hoisted, moved, and placed accurately. Their main goal is to provide a firm link between lifting gear and hefty concrete pieces. This reduces dangers during transport and setup.

Key Components of a Concrete Lifting Anchor System

A standard Concrete Lifting Anchor System includes several essential parts. The anchor, typically crafted from robust materials, serves as the central piece. Other features like threaded inserts, embedded loops, and junction boxes may be added based on the task. These parts collaborate to spread weight evenly. They also preserve strength during lifting activities.

Common Applications of Concrete Lifting Anchors

Concrete lifting anchors find use in many areas. They are crucial in precast building projects. Here, items like walls, floors, and roof supports need smooth relocation. In modular structures, these anchors help assemble units off-site prior to shipping. They’re also key in large-scale works such as bridges and tunnels. Plus, they assist in emergency relief by aiding the setup of temporary housing.

Types of Concrete Lifting Anchors

Overview of Different Types of Lifting Anchors

Concrete lifting anchors vary to suit distinct construction demands. Two main kinds exist: Double head crane anchor and Single head lifting anchor.

Cast-in Lifting Anchors

Cast-in lifting anchors get placed into concrete as it’s poured. They’re built to manage set load limits. They work well for precast parts needing exact placement.

Post-installed Lifting Anchors

Post-installed lifting anchors are fixed into concrete after it hardens. They provide options for updating or altering existing builds. Yet, they demand careful fitting to meet safety rules.

Material Composition of Lifting Anchors

The makeup of lifting anchors affects how well they perform. Most are made from tough steel or strong alloys. These materials resist heavy forces without bending or breaking. The material picked also hinges on surroundings—like wetness or harsh substances.

How a Concrete Lifting Anchor System Works

The Mechanics Behind Load Distribution

The strength of a Concrete Lifting Anchor System comes from its load-sharing ability. When weight is applied, the anchor passes stress through its fixed section into the nearby concrete. This setup avoids focused pressure points. Such points could cause the structure to fail.

Installation Process for Concrete Lifting Anchors

Fitting a concrete lifting anchor takes multiple steps. For cast-in types, exact positioning in molds is critical before concrete is added. Post-installed ones need holes drilled into set concrete. Then, they’re secured with glue or hardware.

Benefits and Importance of Using Concrete Lifting Anchors

Ensuring Safety During Heavy Lifts

Concrete lifting anchors boost safety by offering trusty connection spots for big lifts. This cuts down on risks from gear breakdowns or poor handling methods.

Enhancing Efficiency in Construction Projects

These systems speed up moving and placing precast parts. They improve workflow on building sites. They also help finish projects quicker while trimming labor expenses.

Factors to Consider When Choosing a Concrete Lifting Anchor

Load Capacity and Weight Requirements

Picking an anchor with enough load strength is vital for safety and use. Engineers must figure out weight needs tied to the job at hand.

Environmental Conditions and Material Durability

Weather factors like dampness, heat shifts, and chemical exposure shape material choices for lifting anchors. Tough options like coated steel or stainless steel often suit harsh settings.

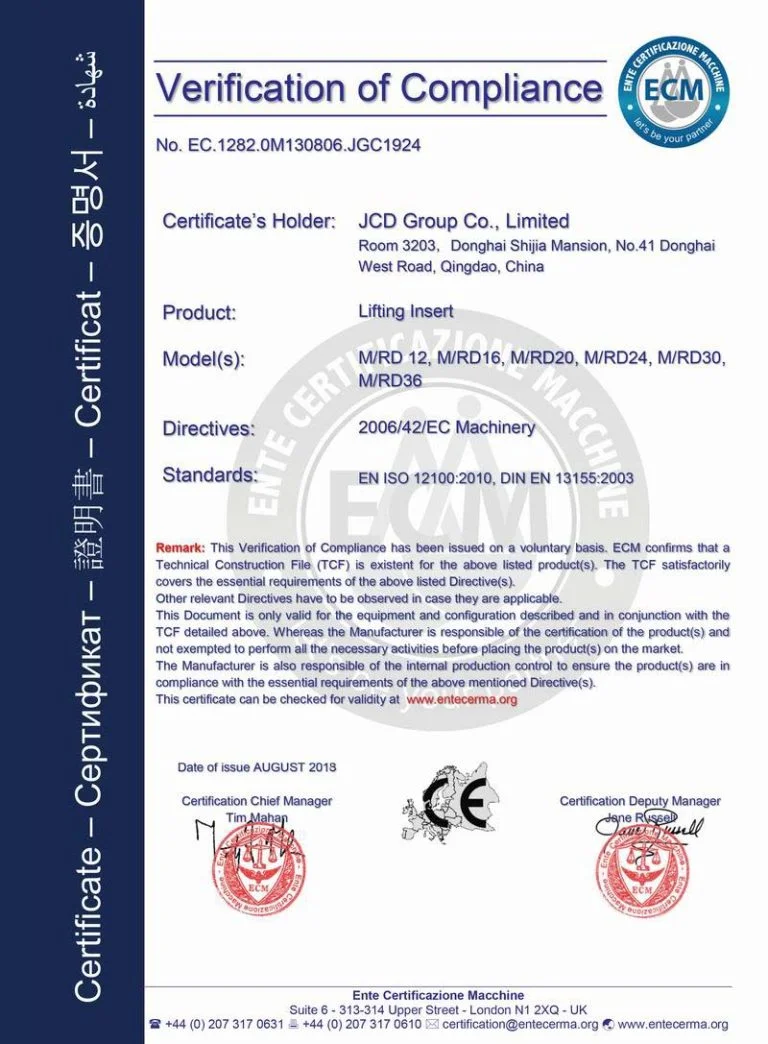

Compliance with Industry Standards

Concrete Lifting Anchor Systems must follow trade rules and approvals. This ensures they’re dependable and safe during use.

Maintenance and Inspection of Concrete Lifting Anchors

Regular Inspection Practices for Safety Assurance

Ongoing checks are key to spotting issues with lifting anchors. Look for rust or shape changes often. Load tests should happen when needed.

Common Signs of Wear or Damage in Lifting Anchors

Clues like cracks in nearby concrete or worn metal surfaces suggest an anchor might not be safe anymore. Quick fixes or swaps are needed if these show up.

Frequently Asked Questions

What is a concrete lifting anchor?

A concrete lifting anchor is a tool set into precast concrete parts. It helps with their safe handling during shipping and setup.

What types of materials are used in making these anchors?

Strong steel or lasting alloys that resist rust and wear are common choices.

Where are concrete lifting anchors typically applied?

They’re used a lot in precast building tasks, modular setups, big projects like bridges, and relief efforts.

How do I ensure proper maintenance of these systems?

Routine checks for wear or harm, plus sticking to maker tips, keep them working well over time.

Why choose BaoQi’s customization service?

BaoQi provides tailored options for your project’s needs. They boast ISO-9001 certified quality with over a decade of skill.

For more details on top-notch products built for construction success, check BaoQi’s official site at https://www.baoqitech.com/