In the world of construction and heavy lifting, safety and efficiency in load distribution are cardinal to successful operations. Be it precast concrete, machinery, or steel beams, proper load distribution prevents accidents, reduces wear on equipment, and extends the life of your lifting devices. One of the most effective tools in achieving optimal load distribution is the lifting loop.

A simple yet powerful device, the lifting loop evenly distributes weight across lifting equipment. Although it might be easily overlooked, the benefits of using lifting loops in construction and manufacturing run deep.

We will also focus on how BaoQi, being one of the leading high-quality lifting equipment companies, can provide you with both the tools and know-how to help improve your lifting processes with their tough, reliable lifting loops.

Introduction: Why Proper Load Distribution Matters

Load distribution in lift operations is of paramount importance, as a badly balanced load may result in severe safety risks, machinery damage, and many operational inefficiencies. Lifting loops are attached with the lifting hooks to the load to be lifted and serve for weight distribution.

A lifting loop is designed to be able to distribute the load across the lifting equipment, preventing damage and providing a safe and reliable means of handling heavy items. These loops help distribute the weight evenly, allowing the lifting operation to be far safer, faster, and more efficient.

What is a Lifting Loop and How Does It Work?

A lifting loop is a circular device designed for lifting. It works by connecting a lifting hook to a load and distributes the weight in the right manner. Generally, loops used in lifting are made from premium steel wire, which may be twisted into several strands to form a rope that can endure quite high tension and weight. These loops have the high strength required so that it endures being subjected to heavy loads without deforming or even wear and tear.

Salient Features of Lifting Loop by BaoQi

- High Strength: BaoQi’s lifting loops are manufactured from high-strength steel so that it is very durable. The usage of the loop becomes applicable in the lifting of heavy materials like precast concrete slabs, steel beams, and large machinery.

- Tensile Performance: Lifting loops are designed with high tensile strength in mind to handle extreme stressors without failing due to either breakage or stretching. This ensures the safety of the lifting operation and integrity of the equipment.

- Durability: Lifting loops from BaoQi are treated for corrosion resistance and wear resistance to make them more durable for a long life and functionality over several usages. It extends the service life and hence is value for money.

- Stability:The design of BaoQi’s lifting loops ensures that they maintain stable performance over time, even with regular use. The loop’s twisted wire structure reduces the risk of deformation, ensuring that it holds its shape and performs consistently.

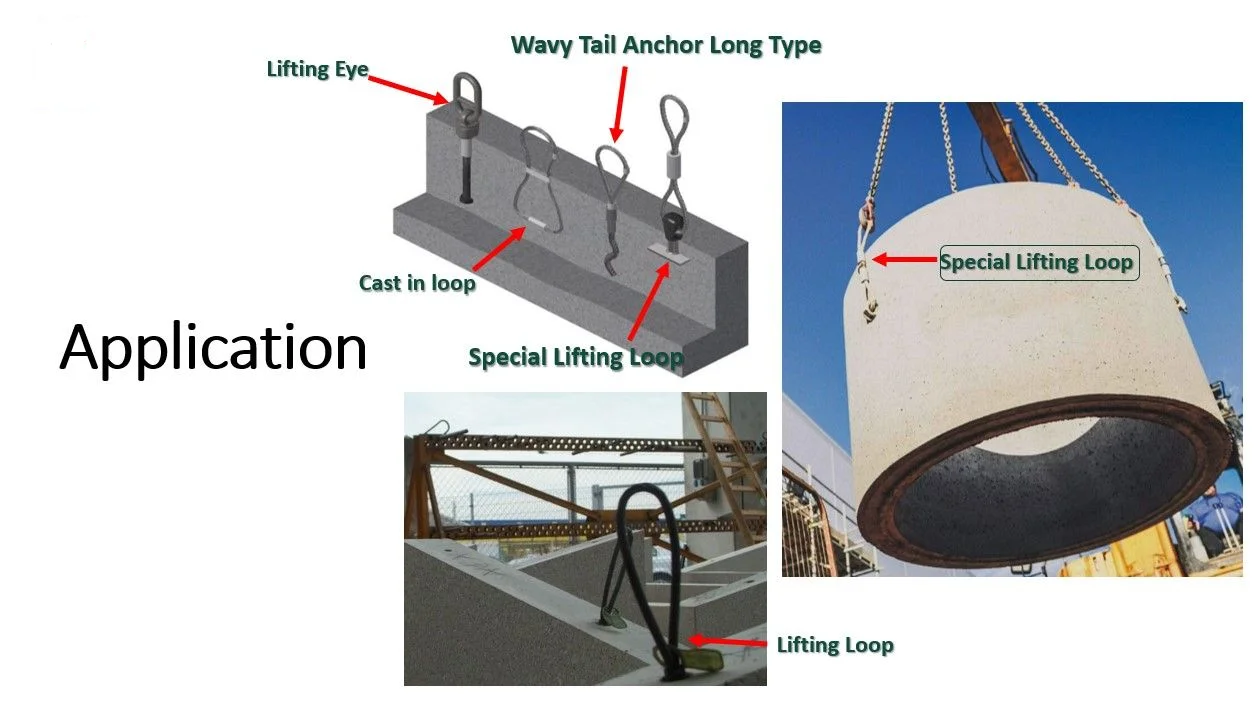

Applications of the Lifting Loop

Lifting loops are versatile and can be used in various applications across different industries, including:

Manufacturing and Warehousing: Lifting heavy equipment, machinery parts, and raw materials.

Construction: During lifting of building materials, such as precast concrete elements, beams, and slabs.

Logistics and Transport: The attachment of lifting slings or hooks provides an easy and speedy transportation of merchandise.

This automatically makes the lifting loops highly useful for those types of industries, in which sharing the weight is a matter of utmost prominence.

Good Practice to Maximise Load Distribution Using Lifting Loops

1. Choose the Right Type of Lifting Loop for the Operation

The right choice of lifting loop for the weight and type of load is very important for maximum load distribution. BaoQi offers a lifting loop ranging from 1.3T to 32T with different specifications for tailored solutions to meet the demands of the job.

Tip: Always check the safe working load (SWL) for the lifting loop. Overloading a lifting loop can lead to failure and cause terrible accidents.

2. Proper Placement of Loop

Correct placement of the lifting loop will ensure proper distribution of weight in the right amount. The lifting loop should be placed in such a way that it distributes the weight of the load correctly across the hook, crane, or any lifting system.

Pro Tip: Use multiple lifting points whenever possible, especially for heavy or oversized loads. This allows for better balance of the load and prevents overloading on one side of the lifting system.

3. Regular Maintenance and Inspection

Like all lifting devices, the lifting loop does need regular aintenance and inspection to perform well. In particular, the inspection of the lifting loop for wear and corrosion is at the point of contact made by the lifting hooks to extend its lifetime and maintain its safety features.

Report: According to a study conducted by the Lifting Equipment Engineers Association, LEEA, 70% of lifting-related accidents are due to poor maintenance or incorrect use of lifting equipment. Regular inspections ensure that any damage or wear is isolated from the opportunity to present a safety risk.

4. Use Lifting Loops in Conjunction with Other Equipment

In complicated lifting operations, a lifting loop can be used in conjunction with other equipment, such as slings, chains, and cranes, to facilitate weight distribution and safety. Proper integration of lifting devices is the only way to optimize weight distribution during lifting operations.

Industry Insight: According to Cranes and Lifting Magazine, the use of lifting loops in combination with proper rigging techniques can reduce lifting times by up to 30% and improve load handling precision.

5. Avoid Sharp Angles in the Lifting Loop

In operations where one has to deal with the lifting loops, it should never be allowed to remain at sharp angles. This can cause uneven tension in the lifting, resulting in the damage of any equipment. Try to keep the loop as straight as possible for appropriate distribution of the load.

Best Practice: If necessary, use spreader beams or lifting slings to keep the lifting loop in a straight line and reduce the angle of the lifting operation.

The Benefits of Using BaoQi’s Lifting Loops

BaoQi has been well recognized for the excellent quality of its lifting loops designed for load distribution with maximum safety. BaoQi manufactures its lifting loops with extreme attention to detail by using high-strength steel and an advanced manufacturing technique in order to create durable and reliable products that meet the standards for safety around the world.

Why Choose BaoQi Lifting Loops?

Quality Assurance: BaoQi’s lifting loops are manufactured through ISO 9001 certified processes, which ensure that the highest standards concerning strength, durability, and performance are met.

Customization: BaoQi provides custom lifting loops to meet particular needs for your project. Be it lifting heavy construction material or machinery, BaoQi has something that fits your requirements.

Durability: The corrosion and wear-resistant treatment of the lifting loops by BaoQi ensures a long service life and safety even in the most adverse conditions.

Global Reach: Products offered by BaoQi find their place in service almost everywhere around the world, from Australia to Denmark, France, and Germany. Thus, the name BaoQi has become synonymous with lifting equipment.

Conclusion: Optimize Load Distribution with BaoQi’s Lifting Loops

Lifting loops are important in the distribution of load for safety and efficiency during a lifting operation. With BaoQi’s high-quality lifting loops, you are guaranteed that your lifting processes are safe, efficient, and long-lasting. From building sites to factories, proper usage of lifting loops guarantees heavy loads will be evenly distributed to reduce wear on equipment, prevent accidents, and improve operational efficiency.

Your investment in quality at BaoQi will be an investment in the safety and efficiency of your lifting operations. With customized solutions, durable materials, BaoQi can supply the perfect solution for every lifting operation.