In today’s industrial field, which is moving at fast speeds, downtime is one of the greatest cost factors a company looks to minimize. Lifting, therefore, plays a huge role in ensuring that workflows are optimally maintained, particularly for industries like construction, mining, and heavy manufacturing.Rapid Lifting Systems are designed to shorten the lifting time, enhance dependability, and consequently guarantee maximum uptimes. The system introduces new ways that industries carry out heavy materials handling: faster, safer, and more efficiently.

In this blog, we look at howRapid Lifting Systems improve operational efficiency, their benefits to different industries, and how businesses can choose appropriate systems for their operations. We will also highlightBaoQi, one of the leading manufacturers in the industry, offering advanced lifting solutions to global markets.

The Importance of Uptime in Industrial Operations

Uptime in any industrial setting is one of the most important metrics because it directly affects productivity, safety, and profitability. Each minute of downtime means production delay, costly repairs, and possibly dangerous situations. For industries where heavy lifting is common—whether in construction material movement, machinery, or large-scale components—the reliability of lifting systems becomes important.

Rapid Lifting Systems are designed to reduce the time required to perform lifting tasks while enhancing the overall safety and precision of the operation. These systems depend on advanced technologies, high-quality components, and efficient engineering that ensures lifting operations can be done in minimal time without sacrificing performance.

How Rapid Lifting Systems Optimize Lifting Efficiency

1.Enhanced Speed and Precision

Key advantages of Rapid Lifting Systems are the much shorter completion time in lifting operations. Heavy loads can be moved with this type of system using either strong hydraulic or electric motors while retaining a lot of control.

Unlike traditional lifting systems, which may require manual adjustments or multiple operators,Rapid Lifting Systems feature automated controls and advanced sensors that ensure smooth and precise operations. These advancements reduce the need for human intervention, which decreases the likelihood of errors and injuries.

The integration of modern automation technology enables lift systems to handle repetitive duties at high speed and with hardly any time wasted between cycles. This is particularly important for industries dealing with construction,mining, and logistics, where time means money, literally, and every second counts.

2.Safety and Reliability

In high-risk environments such asconstruction sites and warehouses, safety is a top priority. Traditional lifting methods often involve manual labor or older mechanical systems, which increase the likelihood of accidents and downtime due to equipment failure.

Safety features for Rapid Lifting Systems include automatic overload protection, emergency stop systems, and anti-sway technologies that minimize accidents. Advanced systems generally employ load cell technologies and sensors that work in concert to balance the weight of the load, making imbalance and failure less probable.

These safety mechanisms can be put in place to minimize the frequency at which companies experience operational disruption due to malfunctioning pieces of equipment or unsafe practices. This will maximize uptimes and keep workers a great deal safer.

3.Increased Durability and Longevity

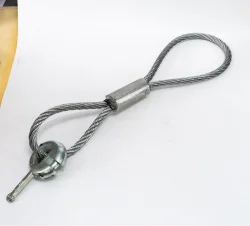

Rapid Lifting Systems are engineered for long-term performance. Many systems boast high-strength materials capable of withstanding severe working conditions: extreme temperatures, high moisture, and heavy impacts. It is the robustness of the systems that has become a key factor in their consistent functioning over time with minimal maintenance.

Companies that invest in these systems can enjoy lower maintenance costs, reduced downtime due to repairs, and longer equipment life cycles. Besides, many modern lifting systems are equipped withself-diagnostic tools that warn operators against impending problems before they occur for due maintenance to be performed on time and thus avoid costly downtime.

Key Benefits of Rapid Lifting Systems

1.Maximized Productivity

Rapid Lifting Systems assist businesses in raising productivity through time reduction in lifting operations and enhanced reliability. The ability to handle materials at a quicker pace allows workers to carry out more tasks in a certain amount of time, thereby contributing to overall efficiency. This might substantially up profitability in high-volume industries.

For instance, in construction, the ability to lift and position heavy beams or panels fast can reduce project timelines, allowing companies to meet deadlines and take on more projects. Similarly, in warehouses, fast and reliable lifting systems enable quicker stock retrieval and order fulfillment.

2.Cost-Effective Operations

While the initial investment in the Rapid Lifting Systems may seem high, the long-term benefits far offset the cost. These systems not only reduce downtime but also cut labor to a minimum because automated lifting reduces reliance on human operators, thus saving labor costs.

Besides, the longer service life and low maintenance requirements of contemporary lifting systems translate into companies saving money on repairs and replacement over the years.Rapid Lifting Systems are, therefore, a cost-effective solution that provides a strong return on investment (ROI).

3.Adaptability and Versatility

Fast-lift systems can be found in numerous configurations: mobile, stationary, and modular. Further, these work in quite different configurations for use on anything from the small-scale warehouse to major construction sites or mining. It also makes the system suitable for business enterprise through flexibility in its ability to make changes that would better suit its particular requirements.

Whether it’s heavy equipment, construction materials, or machinery, the rapid lifting systems can be integrated into existing operations with ease to enhance overall workflow and efficiency.

Choosing the Right Rapid Lifting System for Your Business

When considering a Rapid Lifting System, there are several factors to take into account:

1.Capacity and Load Requirements

The weight a system can lift is one factor of great concern. For businesses, the idea of being able to handle material or equipment weight is always of interest. Different systems operate with different weight limits, thus a system that can actually cope with the weight as well as the nature of the load to be lifted–such as irregular shapes or heavy machinery–should be selected.

2.Worksite Environment

The operating environment of the system, which will determine what exactly the right lifting solution may look like. For instance, the outdoor construction site environment may require more heavy-duty systems that can manage such harsh weather conditions. On the other hand, in door warehouse conditions could do with more compact and versatile systems.

3.Integration with Technology

Modern lifting systems come equipped with smart technology, such as remote control capabilities. These features can be extremely beneficial for optimizing workflow and ensuring safety. Look for systems that offer seamless integration with existing equipment and control systems.

BaoQi’s Rapid Lifting Systems: A Trusted Solution for Your Business

As a leading manufacturer of Rapid Lifting Systems, BaoQi is committed to the highest quality solutions to meet demanding industries across the world. With over a decade of experience in producing advanced lifting systems, the products designed by BaoQi aim at maximum efficiency, durability, and safety.

BaoQi’s Rapid Lifting Systems are built with cutting-edge technology and engineered to reduce downtime while boosting operational performance. The company’s four production plants in Weifang and Qingdao ensure that every product meets international quality standards, includingISO-9001 certification. With products sold acrossEurope,North America, andAustralia, BaoQi has earned a reputation for reliability and innovation.

Whether you need construction,manufacturing, or logistics lifting solutions, BaoQi can provide relevant systems to optimize your operations. BaoQi is a one-stop-shop with highly specialized professionals in in-house design and engineering and offers total customer satisfaction, which means BaoQican become an ideal partner for your company looking to develop their lifting competencies.

Conclusion

The rapid lifting system is a necessity for companies in their quest to ensure uptime, safety, and increased productivity. With the proper selection of a system, the company will be guaranteed efficiency and reliability in its operations of lifting, hence reduced downtime and increased profit margins.

BaoQi, with its accumulated experience and quality commitment, stands as a reliable provider for advanced lifting solutions that can support your company’s competitive advantage in this rapidly changing industrial environment. Take your operations to new levels today-invest inBaoQi’s Rapid Lifting Systems.