Importance of the Combination Swivel Loop in Lifting Operations

During lifting operations in industries, safety and efficiency are priorities. The Combination Swivel Loop plays a role in improving these factors. This tool guarantees a seamless lifting process making it essential for a range of industrial uses.

Enhancing Safety Standards

Safety is a priority during lifting operations as the Combination Swivel Loop aims to enhance safety by establishing a link between lifting gear and loads. Its sturdy design guarantees secure load holding to diminish the chances of accidents resulting from slippages or detachments. Integrating this element into your lifting arrangement can elevate safety measures. Safeguard your team from danger.

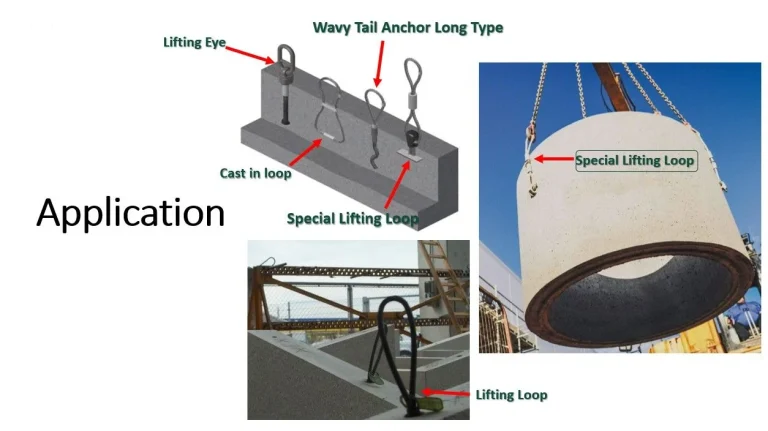

Versatility and Application

The Combination of Swivel loop versatility makes it perfect for use Be it handling machinery constructing buildings or moving goods around. As it can adjust to different situations easily. Its swiveling function enables movement in angles and positions while keeping everything stable. This flexibility is key for tasks that demand control over where the load is placed.

Technical Specifications and Design Features

To choose the Combination Swivel Loop for your requirements, it’s essential to grasp the details and design characteristics of the product as these factors play a crucial role in its functionality and appropriateness, for different uses.

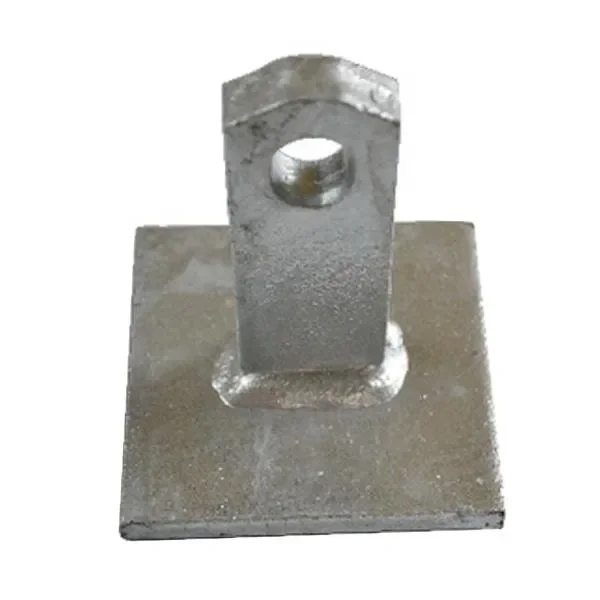

Innovative Design Elements

The clever layout of the Combination Swivel Loop integrates aspects that improve its usefulness –, like versions featuring linked rings for added safety during lifting tasks. The employment of top-notch tech materials guarantees longevity and resilience against damage. Wear in situations. These design characteristics establish the Combination Swivel Loop as an option, for industrial settings.

Load Capacity Considerations

When you’re picking out a Combination Swivel Loop it’s crucial to take into account its load capacity. This tells you the weight it can handle safely without any issues cropping up during operation or equipment breakdowns. To keep things safe and running smoothly make sure to evaluate your needs and opt for a loop that meets or surpasses these requirements for maintaining both safety and effectiveness.

Choosing the Right Combination Swivel Loop for Your Needs

Choosing the Combination Swivel Loop involves the assessment of different aspects that pertain to your particular operational requirements.

Assessing Operational Requirements

Start by evaluating your needs to figure out which type of Combination Swivel Loop would be the most suitable, for your requirements. Take into account aspects like the weight of the loads you usually deal with and the environmental conditions under which you work. Also, consider any safety regulations that you need to follow. This evaluation will help you choose a loop that fulfills all the criteria, for your operations.

Factors Influencing Selection

When picking a Combination Swivel Loop for your needs, it’s important to consider factors such, as the quality of materials used the design elements it offers, and how well it fits with your existing equipment setup. You should opt for a product that not only meet the required standards but also blends in well with your current system. It’s also wise to think about expansion possibilities; choosing a loop now could help you avoid extra expenses on replacements or updates, down the line.

Details regarding premium lifting solutions such as the Combination Swivel Loop product line by BaoQi Tech are available for exploration, at their website. The company’s offerings showcase engineering to cater to a range of industrial requirements effectively.

By examining these factors—you can be certain that selecting a Combination Swivel Loop will improve safety and efficiency in your lifting tasks.

Maintenance and Inspection Protocols

Ensuring the Combination Swivel Loop is regularly checked and maintained is essential for its longevity and peak performance during tasks. Develop a method for these procedures to minimize the chances of equipment breakdowns.

Routine Inspection Procedures

Regular checks should be done to spot any wear and tear issues by inspecting the swivel mechanism, for movement checking the interlocking rings’ condition, and making sure all parts are free from rust and damage. In environments, with moisture or dust exposure maintenance lubrication may be necessary to keep the swivel working.

Troubleshooting Common Issues

With upkeep efforts, in place for the Combination Swivel Loop mechanism can still encounter problems from time to time. Typical issues involve limitations in movement caused by debris accumulation and the impact of worn-out parts affecting their ability to handle loads effectively. To address these concerns involves tasks such, as cleaning the swivel components and replacing any elements while also making adjustments to recalibrate the loop as needed. Crucially important is to have all repair work carried out by individuals to uphold safety protocols at all times.

Partnering with Industry Leaders for Quality Assurance

Working together with known manufacturers guarantees that you have access, to top-notch lifting parts such as the Combination Swivel Loop ensuring that you get products crafted for quality by partnering with leaders, in the industry.

BaoQi’s Commitment to Excellence

Standing out as a frontrunner in the industry of premium lifting solutions is BaoQi with its dedication to excellence showcased through testing protocols and strict compliance with global safety regulations. Opt, for BaoQi and experience cutting-edge designs supported by research and development endeavors.

Discover the array of lifting products offered by BaoQi Tech, by checking out their range available for exploration on their website BaoQi Techs online platform.

Product Spotlight: Combination Swivel Loop

BaoQi Combination Swivel Loop showcases its commitment to engineering with its build meant for high durability and efficiency in challenging settings. For information on specs and how to buy it head over to the Combination Swivel Loop page.

Future Trends in Lifting Equipment Technology

The lifting equipment sector is set for progress due to advancements and breakthrough developments in material science.

Advancements in Material Science

New materials with improved strength-to-weight ratios, boost load capacities without bulk for efficiency in lifting tasks through reduced energy use and enhanced maneuverability.

Technological Innovations on the Horizon, the advancements could involve the integration of technology to enable monitoring equipment status in real-time using IoT devices. These advancements offer the potential for safety by providing maintenance alerts and automatic adjustments during lifting operations.

By keeping up to date with these developments and trends in the industry landscape, you place yourself ahead in the field of advancements and guarantee that your business stays competitive and secure even as the environment continues to change.