Understanding Ring Clutches and Lifting Clutches

What Are Ring Clutches and Lifting Clutches?

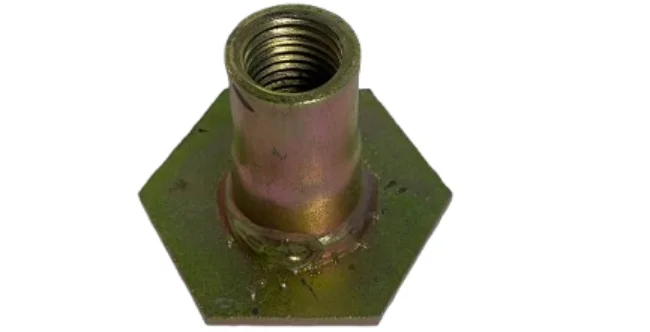

Ring clutches and lifting clutches are essential components used in the precast concrete industry. They are designed to safely and efficiently lift and transport heavy concrete elements. These clutches are crucial for ensuring the stability and security of loads during handling operations.

How Ring Clutches Work

Ring clutches operate by engaging with a corresponding lifting anchor embedded in the concrete element. The ring design allows for a secure grip, distributing the load evenly across the clutch. This mechanism ensures that the concrete is lifted without causing any damage, maintaining structural integrity.

How Lifting Clutches Work

Lifting clutches, on the other hand, function by attaching to a lifting eye or loop that is integrated into the concrete piece. The clutch’s design facilitates quick attachment and detachment, making it ideal for repetitive lifting tasks. It provides a reliable connection that withstands significant weight while minimizing wear on both the clutch and the concrete.

Ring Clutch vs. Lifting Clutch Comparison

Applications of Ring & Lifting Clutches

Ring clasps are primarily employed in scenarios that call for alignment like panels or structural parts that need precise placement… Hoisting clasps offer flexibility. Are ideal, for various uses such as beams and slabs, in construction projects where speed and productivity are key concerns.

Types of Ring Clutches and Lifting Clutches

There are various types of ring clutches available, each tailored to specific load requirements and anchor configurations. Similarly, lifting clutches come in different designs to accommodate varying load capacities and attachment methods. Choosing the right type depends on factors like load weight, lifting method, and environmental conditions.

Choosing the Right Clutch – Key Considerations

Load Weight

When deciding between a ring clutch or a lifting clutch it’s crucial to factor, in the weight of the load, as a consideration. For loads specific designs may be necessary to guarantee both safety and optimal performance.

Lifting Method

The way you lift. Be it up and down or side, to side. Can impact the type of clutch that works best for the job at hand. Basket clutches tend to offer precision for lifts while hoisting clutches allow for versatility, in various angles of lifting.

Environment

Changes, in the environment like temperature fluctuations and exposure to elements can impact how well a clutch performs over time. Thinking about the materials that can handle these conditions is key, to keeping things running.

Frequency of Use

When it comes to tasks that require handling or operation it’s crucial to prioritize durability, above all else. Whether opting for ring clutches or lifting clutches one should consider their capacity to withstand repeated usage without compromising safety standards.

Worker Safety

The safety of workers must always be a priority when dealing with loads. It’s important to assess both kinds of clutches for their safety aspects such, as locking systems and user-friendly features to avoid mishaps while in use.

For those seeking high-quality solutions in this domain, BaoQi offers an impressive range of Lifting Eye/Lifting Clutch products designed to meet diverse needs with precision engineering. Additionally, their specialized Lifting Clutch options provide robust performance across various applications.

In summary of the matter at hand; it is crucial for experienced individuals in the realm of manipulation to discern the differences between ring clutches and lifting clutches thoroughly. For instance; by taking into account elements like the type of application, in question, the prevailing conditions and the safety protocols needed professionals can make thought-out choices that improve operational effectiveness while upholding safety regulations.

Precast Concrete Lifting Methods & Safety

Importance of Safety in Precast Concrete Lifting

When working with precast concrete lifting operations safety is of importance to ensure the well-being of workers and the integrity of the materials being transported and lifted. Utilizing the equipment, like ring clutches and lifting clutches plays a role, in upholding safety standards and preventing accidents while handling heavy concrete elements.

Ring clutches are frequently used for their ability to securely grip and distribute loads to reduce the likelihood of element damage. The hand-lifting clutches offer easy attachment and removal processes that support smooth operations and maintain load stability.

Employers and supervisors should make sure to provide training, for employees regarding the use of such tools and conduct regular checks to detect any signs of wear or malfunctions, in the machinery. Following these guidelines does not ensure the safety of workers. Also improves overall productivity.

FAQs on Ring & Lifting Clutches

Common Queries Addressed

Industry experts frequently raise inquiries, about the application of ring clutches and lifting clutches in their field of work.

- What are the differences in applications between ring clutches and lifting clutches?

- How do I determine which clutch type is suitable for a specific project?

- What maintenance procedures should be followed to ensure longevity?

Understanding the importance of grasping the functionality and practical uses of types of clutches is emphasized by these inquiries.

Lifting Clutch VS Lifting Ring Clutch: Definition, Working Principle, Application Scenarios, and Selection Guide

Ring clutches are created with a mechanism that locks into embedded anchors within structures for precise control during lifting operations. The hand-lifting clutches attach to built-in loops or eyes found in components to offer flexibility across different tasks.

The operational concept of ring clutches revolves around evenly distributing the weight through their structure to maintain stability when lifting vertically. These clutches work by connecting to installed loops or eyes to enable smooth operations without jeopardizing load safety.

Ring clutches are perfect, for tasks that demand placement like panels and excel in situations where alignment accuracy is crucially important. On the hand lifting clutches offer versatility and are well suited for use, with beams, slabs and other precast elements where speed plays a key role.

Choosing between a ring clutch and a lifting clutch depends on factors.

- Load Weight:Assessing the weight capacity required ensures that the selected clutch can handle the demands safely.

- Lifting Method:Consider whether vertical precision or horizontal flexibility is needed.

- Environment:Evaluate environmental conditions like exposure to corrosive elements that could affect material performance.

- Frequency of Use:Opt for durable designs that withstand repetitive use without degrading safety.

- Worker Safety:Select products with robust safety features to protect operators during handling tasks.

If you’re looking for options in lifting precast concrete pieces up high and proud with ease and safety in mind BaoQi has got you covered with a wide range of top-notch Lifting Eye/Lifting Clutch offerings crafted for outstanding performance, in various scenarios. Their lineup of Lifting Clutch choices truly showcases their dedication to delivering top-tier quality and exceptional results.

Experts who handle precast concrete need a grasp of the differences, between ring clutches and lifting clutches to ensure safety and efficiency on site while taking into account load needs and safety guidelines.