Understanding Concrete Block Lifting Tools

The Importance of Proper Lifting Equipment

Choosing the appropriate equipment for lifting concrete blocks is essential to ensure the safety and efficiency of your projects. The right lifting tools can greatly minimize the risk of accidents and injuries on site, which is critical for maintaining a safe working environment. Beyond ensuring safety, proper lifting equipment can improve productivity by enabling workers to move heavy blocks more quickly and with less physical effort. This leads to better workflow management and faster project completion times.

Types of Concrete Block Lifting Devices

There are numerous types of devices designed for lifting concrete blocks, each suited for different scenarios and requirements. Basic manual lifters, mechanical grabs, and hydraulic lifters are among the most commonly used types. Manual lifters are typically used in smaller-scale projects and for lifting lighter blocks. Mechanical grabs offer more control and are suitable for moderately heavy blocks, while hydraulic lifters are optimal for heavy-duty applications where efficiency and strength are critical. Each type of device offers its own advantages and trade-offs in terms of cost, ease of use, and operational capacity.

Introduction to Concrete Block Lifting Clutches

What is a Concrete Block Lifting Clutch?

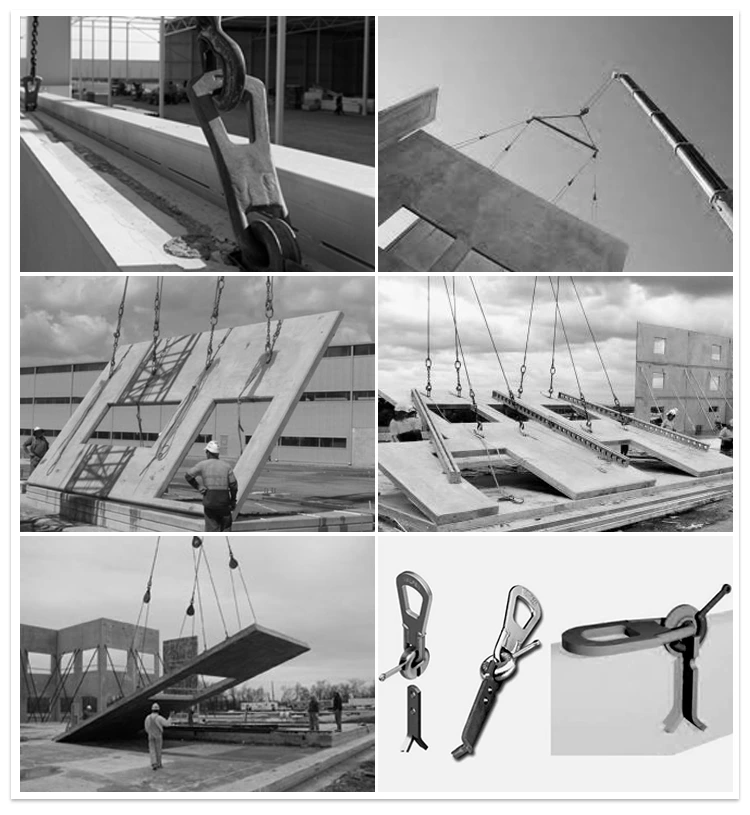

A concrete block lifting clutch is a specialized tool designed to securely lift and maneuver concrete blocks, particularly those used in construction activities. This type of lifting clutch often features a robust metal body with a unique locking mechanism that ensures the block is held firmly during transportation. The clutch is typically attached to a crane or other lifting machinery and manipulated to move blocks precisely into place. These devices are crucial for safely handling heavy blocks and minimizing the risk of accidental drops or misplacements.

Key Benefits of Using Lifting Clutches

The key benefits of utilizing a concrete block lifting clutch include improved safety, efficiency, and versatility. By firmly securing the block during lifts, the clutch greatly reduces the chances of material damage and worksite injuries. Moreover, lifting clutches ease the process of transporting blocks, allowing for quicker project progression. These tools are extremely versatile, accommodating various block sizes and shapes, which makes them invaluable on construction sites with diverse lifting requirements. Furthermore, the use of lifting clutches translates to less physical strain on workers, fostering a healthier and more productive work environment.

Factors to Consider When Choosing a Lifting Clutch

Load Capacity Requirements

When selecting a concrete block lifting clutch, one of the primary factors to consider is its load capacity. It is crucial to choose a clutch that can comfortably handle the maximum weight of the blocks you plan to lift. Overloading a lifting clutch can result in equipment failure and pose significant safety risks. Therefore, it is important to assess both the maximum and average weights of the blocks and select a clutch that offers an adequate safety margin. Always verify the manufacturer’s specified load limits and make sure that the clutch meets or exceeds those requirements for your specific application.

Material Quality and Durability

The quality and durability of the materials used in the construction of a concrete block lifting clutch are critical for its long-term performance. High-quality steel or other strong alloys are commonly used to manufacture these clutches, offering the strength needed to handle heavy loads. Additionally, durable materials resist wear and tear, which is particularly important in construction environments where equipment is subjected to rigorous use. Ensure that the clutch you choose is built with premium materials and that its design has been tested to withstand harsh working conditions over extended periods.

Ease of Use and Maintenance

Ease of use and maintenance are crucial considerations for any concrete block lifting clutch. A clutch that is user-friendly can significantly reduce the time required for training and enhance overall operational efficiency. Look for features such as intuitive locking mechanisms and ergonomic handles that make the device simple to operate. Similarly, maintenance needs should be minimal. A clutch that requires frequent and complex maintenance can lead to downtime and increased costs. Therefore, opt for models that offer easy access to parts and straightforward maintenance routines.

Compliance with Industry Standards

Lastly, ensure that the concrete block lifting clutch you choose complies with industry standards and safety regulations. Compliance guarantees that the product has been tested and deemed safe for use in your specific applications. Check for certifications from recognized bodies and verify that the clutch meets all necessary regulatory requirements. This step is essential not only for legal compliance but also to provide peace of mind, knowing that you are using equipment that adheres to strict standards of safety and reliability. Compliance also often means better insurance rates and less liability in case of workplace incidents.

Introducing BAOQI: A Trusted Name in Lifting Solutions

Overview of BAOQI’s Expertise

BAOQI is esteemed as a foremost provider in the field of lifting solutions, especially for construction and industrial applications. With extensive experience in the sector, BAOQI has earned a reputation for dependability and innovation. Their team of engineers and specialists is committed to creating top-quality products that meet the stringent demands of contemporary construction sites. Through ongoing research and development, BAOQI guarantees that their lifting solutions remain at the cutting edge of technological progress, delivering customers superior performance and safety.

BAOQI’s Range of Lifting Clutches

BAOQI offers an extensive range of lifting clutches designed to cater to various lifting needs. Their concrete block lifting clutch collections are meticulously crafted to provide maximum efficiency and safety. The range includes clutches suitable for different load capacities, ensuring that there is a reliable option for any project scale. Each clutch is manufactured from high-grade materials to withstand the toughest of conditions, and they incorporate intuitive features for ease of use. BAOQI’s lifting clutches stand out for their durability, making them a long-term investment for any construction firm.

Testimonials

Customers have lauded the effectiveness and dependability of BAOQI‘s concrete block lifting clutch. One client stated, “Using BAOQI’s lifting clutches transformed our entire lifting process. The equipment is incredibly user-friendly, and its superior build quality gives us confidence that we are working with the highest standard of tools available. It’s clear that a lot of thought and expertise went into the design of these clutches.”

The real-life applications and glowing customer testimonials underscore the value that BAOQI’s lifting solutions bring to their clients. Whether for high-rise buildings, bridges, or other heavy-duty construction projects, BAOQI’s concrete block lifting clutch remains a trusted choice for safe, efficient, and effective lifting operations.

By choosing BAOQI, businesses can rest assured that they are investing in superior quality and innovative technology that will stand the test of time and meet the demanding needs of their construction projects.