Overview of a Lifting Loop

Definition of a Lifting Loop

A lifting loop is a specialized component used in various lifting tasks to enhance safety and efficiency. It typically comprises a looped structure, often fabricated from high-strength materials such as steel or synthetic fibers, designed to bear heavy loads. Lifting loops are integral in securely attaching loads to lifting equipment, ensuring stability and reducing the risk of accidents during lifting operations. Their design can vary depending on their application, but the primary function remains the same: to provide a reliable point of attachment that can withstand significant forces.

Historical Context and Evolution of Lifting Loops

The concept of lifting loops is not new; it dates back to early construction and industrial activities where basic ropes and chains were utilized for lifting tasks. Over time, the evolution of materials technology and engineering design has significantly improved the efficiency and safety of lifting loops. Initially, lifting tasks relied heavily on rudimentary loops made from materials such as natural fibers and low-grade metals. However, the industrial revolution and subsequent advancements necessitated more robust and reliable lifting solutions. As industries expanded and tasks became more complex, the need for standardization and enhanced performance led to the development of modern lifting loops, crafted from high-grade steel and advanced synthetic fibers.

Importance in Various Industries

Lifting loops play a crucial role in several industries, providing a safe and efficient means to handle heavy loads. In the construction industry, lifting loops facilitate the safe lifting and positioning of materials such as steel beams and concrete elements. In the maritime and offshore sectors, they are essential for handling equipment and supplies, often under challenging conditions. The transportation and logistics industry relies on lifting loops to secure cargo during transit, ensuring goods are moved safely and efficiently. Additionally, industrial manufacturing benefits from lifting loops for the secure lifting of machinery and large components, enhancing overall workflow and safety standards.

Types of Lifting Loops

Steel Lifting Loops

Characteristics

Steel lifting loops are known for their exceptional strength and durability. They are typically made from high-grade alloy steel, which gives them the ability to withstand substantial loads and harsh environmental conditions. The design of steel lifting loops often features a forged or welded structure, ensuring maximum integrity and resistance to deformation. These loops are finished with coatings such as galvanization or painting to protect against corrosion, thereby extending their service life.

Common Applications

Steel lifting loops are predominantly used in heavy-duty applications where high load capacities are required. Commonly found in construction, they are used to lift steel beams, girders, and prefabricated concrete elements. In the maritime industry, steel loops are employed for hoisting anchors, towing vessels, and handling bulky equipment. The robust nature of steel lifting loops makes them ideal for applications where safety and reliability are paramount, such as in heavy machinery lifting tasks.

Synthetic Lifting Loops

Characteristics

Synthetic lifting loops offer a versatile and lightweight alternative to their steel counterparts. These loops are made from high-strength synthetic fibers such as nylon, polyester, or Kevlar. One of the key characteristics of synthetic lifting loops is their flexibility, which allows them to conform to the shape of the load, distributing weight evenly and reducing the risk of damage. Additionally, synthetic loops are resistant to chemicals, UV degradation, and are less prone to causing injuries due to their lighter weight.

Common Applications

Synthetic lifting loops are widely used in applications where flexibility, weight, and safety are considerations. In the transportation and logistics industry, these loops are used for securing and lifting cargo, providing a safer and more efficient alternative to traditional metal loops. The construction industry also employs synthetic loops for tasks requiring gentle handling of delicate materials, such as glass panels and bespoke architectural components. Moreover, their resistance to environmental factors makes them suitable for artistic and sculptural installations where both aesthetics and functionality are crucial.

Customized Lifting Loops

Characteristics

Customized lifting loops are designed to meet specific requirements of unique lifting tasks. These loops can be crafted from either steel or synthetic materials, or a combination of both, tailored to the size, weight, and nature of the load they are intended to lift. Customized loops often involve bespoke engineering solutions, including unique shapes, sizes, and load capacities, to ensure optimal performance and safety.

Common Applications

Customized lifting loops are essential in specialized industries where standard loops may not suffice. For instance, in aerospace manufacturing, lifting loops must be designed to handle large, irregularly shaped components without compromising structural integrity. Similarly, in the renewable energy sector, customized loops are used for installing and maintaining wind turbines, requiring bespoke solutions due to the complex geometry and weight distribution of the components involved. The ability to tailor lifting loops to specific tasks ensures that even the most challenging lifting operations are conducted safely and efficiently.

Design and Manufacture of Lifting Loops

Materials Used for Manufacturing

The materials used in manufacturing lifting loops are a critical factor in determining their strength and durability. Steel lifting loops are typically made from high-grade alloy steels, known for their tensile strength and resistance to wear and tear. Synthetic lifting loops, on the other hand, utilize advanced fiber materials such as nylon and polyester, chosen for their high strength-to-weight ratio and flexibility. Each material offers distinct advantages, enabling manufacturers to produce lifting loops suited to various applications and environmental conditions.

Steps in the Manufacturing Process

Designing

The design phase involves detailed engineering and planning to ensure the lifting loop meets the required specifications and standards. Engineers use computer-aided design (CAD) software to create detailed models, considering factors such as load capacity, stress distribution, and material properties. This phase is crucial for identifying potential weaknesses and ensuring the loop will perform reliably under operational conditions.

Fabrication

Fabrication is the process of transforming raw materials into the final lifting loop product. For steel loops, this involves cutting, shaping, and welding steel to create the desired form. Synthetic loops are produced by weaving or molding high-strength fibers into the required shape. The fabrication process must adhere to stringent quality standards to ensure the structural integrity and performance of the lifting loops. Advanced techniques such as laser cutting and robotic welding are often employed to achieve precise and consistent results.

Quality Control Measures

Quality control measures are vital in the manufacture of lifting loops to ensure they meet rigorous safety and performance standards. This process involves systematic testing of the materials and finished products to detect any defects or weaknesses. Non-destructive testing methods, such as ultrasonic and magnetic particle inspection, are commonly employed to assess the integrity of the loops without causing damage. These tests help ensure that the lifting loops will reliably withstand the loads they are rated for, minimizing the risk of failure during operation. Additionally, manufacturers may conduct load tests to validate the actual carrying capacity of the loops, ensuring they adhere to specified ratings.

Technical Specifications and Standards

Lifting loops must comply with various technical specifications and industry standards to guarantee their safety and performance. Organizations such as the American Society of Mechanical Engineers (ASME) and International Organization for Standardization (ISO) establish guidelines for the design, manufacture, and testing of lifting equipment. These standards encompass aspects like material properties, load ratings, and safety factors, providing a benchmark for quality and reliability. By adhering to these standards, manufacturers ensure that their products can be confidently used across different industries, fostering trust and safety in lifting operations.

Applications of Lifting Loops

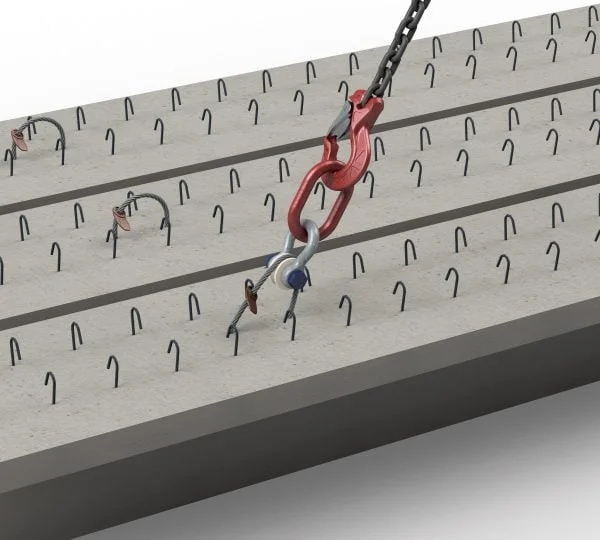

Construction Industry

In the construction industry, lifting loops are indispensable for safely and efficiently handling heavy building materials and components. These loops are used to lift steel beams, concrete slabs, and prefabricated elements, facilitating their precise placement and installation. Their robust design allows them to withstand the rigors of construction sites, where handling large and heavy loads is a regular occurrence. By providing a reliable attachment point, lifting loops enhance the safety and speed of construction operations, minimizing the risk of accidents and delays.

Maritime and Offshore Operations

Lifting loops are also crucial in maritime and offshore operations, where they are used to handle equipment, supplies, and structural components. These environments demand lifting solutions that can withstand corrosive marine conditions and the stresses of offshore operations. Steel lifting loops, with their high strength and corrosion-resistant coatings, are often employed for tasks like hoisting anchors, towing vessels, and installing offshore platforms. Synthetic lifting loops, with their flexibility and resistance to environmental degradation, are also used in these settings for securing and lifting various items safely and efficiently.

Transportation and Logistics

In the transportation and logistics industry, lifting loops play a vital role in securing and moving cargo. These loops are used to attach and stabilize loads during transit, ensuring they remain intact and undamaged. Both steel and synthetic loops are employed depending on the nature and weight of the cargo. Steel loops are preferred for heavy-duty applications such as lifting large containers and machinery, while synthetic loops offer a safer and more efficient solution for lighter, delicate items. Their ability to improve load stability and handling efficiency makes lifting loops an essential tool in logistics operations.

Industrial Manufacturing

Lifting loops are widely used in industrial manufacturing for moving heavy machinery and large components during production and assembly processes. These loops provide a secure and reliable means of lifting, reducing the risk of damage to both the equipment and the components. By facilitating safe handling and precise placement, lifting loops enhance the efficiency of manufacturing operations. They are essential in industries such as automotive, aerospace, and heavy machinery manufacturing, where precision and safety are paramount.

Safety Considerations with Lifting Loops

Load Capacity Ratings

Understanding the load capacity ratings of lifting loops is critical for safe lifting operations. Each loop is designed to handle a specific maximum load, which must not be exceeded to prevent failure. Load capacity ratings are determined based on the materials used, the design of the loop, and the intended application. It is essential for operators to be aware of these ratings and ensure they match the requirements of the lifting task at hand. Using lifting loops within their rated capacity mitigates the risk of accidents, ensuring safe and efficient load handling.

Regular Inspection and Maintenance Procedures

Regular inspection and maintenance of lifting loops are necessary to ensure their continued safety and effectiveness. Inspections should be carried out before each use, checking for signs of wear, damage, or deformation. For steel loops, this might involve looking for cracks, corrosion, or elongation, while synthetic loops should be inspected for fraying, cuts, and UV damage. Maintenance procedures may include cleaning, applying protective coatings, and replacing worn or damaged loops. By adhering to a rigorous inspection and maintenance schedule, operators can prevent failures and extend the service life of their lifting loops.

Common Safety Protocols

Implementing common safety protocols is essential when using lifting loops to ensure safe and efficient operations. These protocols include training personnel on the proper use and handling of lifting loops, ensuring they are aware of load capacity ratings, and adhering to safe lifting practices. Operators should avoid shock loading, which can exceed the loop’s capacity and cause failure. It is also important to use lifting loops in conjunction with other appropriate lifting equipment, such as slings and shackles, to distribute loads evenly. Strict adherence to these safety protocols minimizes risks and enhances the overall safety of lifting operations.

Innovation and Future Trends in Lifting Loop Technology

Advancements in Material Science

Advancements in material science are continually improving the performance and durability of lifting loops. Researchers are exploring new alloys and synthetic fibers that offer higher strength-to-weight ratios and better resistance to environmental factors. Innovations such as nano-coatings can enhance corrosion resistance and prolong the service life of lifting loops. These technological advancements enable the development of stronger, lighter, and more durable lifting solutions, meeting the increasingly demanding requirements of various industries.

Integration with Automation Technologies

The integration of lifting loops with automation technologies is poised to revolutionize lifting operations. Automated lifting systems, equipped with sensors and control systems, can enhance the precision and safety of lifting tasks. Lifting loops designed to work seamlessly with robotic arms and automated cranes can streamline operations, reducing manual labor and minimizing the risk of human error. Additionally, smart lifting loops with embedded sensors can provide real-time data on load conditions and loop integrity, enabling predictive maintenance and further enhancing safety and efficiency.

Continuing advancements in material science and automation technologies promise a future of even more efficient, versatile, and reliable lifting loops, underscoring their critical role in enhancing the safety and efficiency of lifting tasks across various industries. By staying abreast of these innovations, industries can ensure they are equipped with the best tools to meet the challenges of modern lifting operations.

BAOQI maintains a leading position in the field of Lifting Loop production.

BAOQI, established in 2010, is a company based in Qingdao, China, specializing in the production and export of various forging, casting, and punching parts. One of their product lines is the Lifting Loop. The Lifting Loop is a part of their precast and mold accessories range. The Lifting Loop is manufactured to meet the strict quality requirements and industry standards. BAOQI‘s products, including the Lifting Loop, have gained popularity in various countries such as Australia, Denmark, Finland, France, UK, Germany, Canada, USA, and Middle East countries. BAOQI is committed to delivering the best quality products, competitive prices, and timely delivery to their customers. For more information about BAOQI and their products, you can visit their homepage.